BLACK POWDER MILL

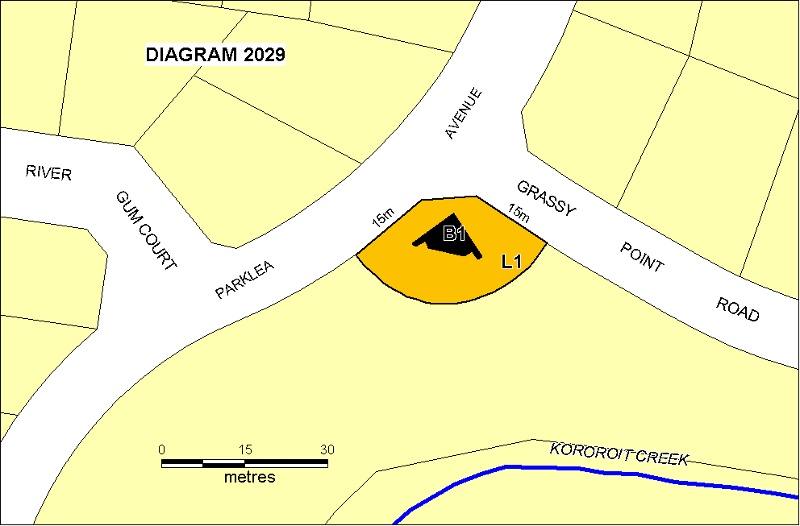

PARKLEA AVENUE AND GRASSY POINT ROAD CAIRNLEA, BRIMBANK CITY

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

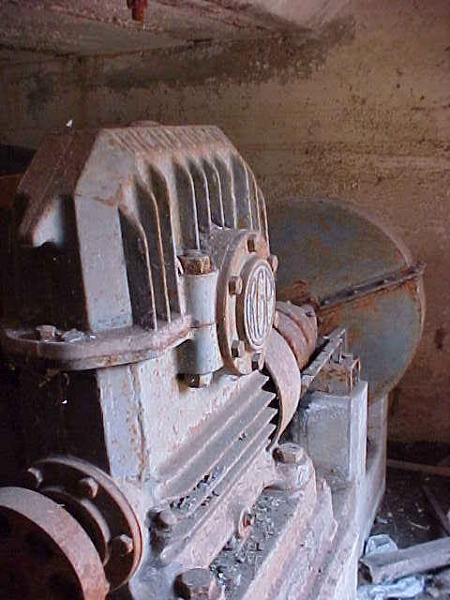

The Black Powder Mill is a concrete and timber framed building housing a Chilean (or edge-runner) mill formerly used to grind the components of gunpowder used principally in time delay fuses for bombs and shells. The building is the last remnant of the former Albion Explosives factory which was set up initially in 1939 as an annex to the nearby ICI explosives factory. The Commonwealth government, in preparing for war had devised a system of co-operation with industry to increase production of strategic materiel. The annex was later taken over by the Commonwealth and used for the production of high explosives until its closure in the late 1980s and the transfer of its function to Mulwala in NSW. The rest of the factory was decontaminated and demolished, but the black powder mill, which for safety reasons was sited on the bank of the Kororoit Creek, survived. The concrete blast walls were designed to direct any blast over the creek valley. The relatively light construction of both the roof and timber framed south wall was designed to be sacrificial. The Chilean Mill with its large rollers, pan and gear box also survive as does the shadow board for the specialised tools.

How is it significant?

The Black Powder Mill is of historical and scientific (technological) significance to the State of Victoria.

Why is it significant?

The Black Powder Mill is of historical significance as the sole remnant of the former Albion Explosives Factory, a key component of Australia's wartime and post-war munitions industry. It is of historical interest for its role in the production of gunpowder for specialised use in fuses for high explosive munitions.

The Black Powder Mill is of scientific (technological) importance for its rare ability to demonstrate an important stage in the manufacture of gunpowder. The building's siting, structure, machinery and tool shadow board all help to demonstrate the dangerous nature of the process and the special precautions taken to minimise damage in the case of an accident.

-

-

BLACK POWDER MILL - History

Source: National Trust Nomination

The Albion Explosives factory was established (on former pastoral land, partially owned by ICI, and compulsorily acquired) to serve as a wartime annexe under a Commonwealth scheme begun in August 1938. Initial construction was undertaken for the Department of Defence/ Munitions Supply Branch by ICIANZ, and the site was initially known as Explosives Annexe No. 5. Later the name was changed to Albion Explosives Factory (AEF). The Commonwealth Government resumed complete control of the works after World War Two.

Initially the factory comprised a T.N.T. section, nitroglycerine plant and cordite section and the first facilities in Australia for the production of nitric and sulphuric acid specifically for military munitions manufacture, the acids being previously obtained from other explosives, fertiliser and chemical works, in particular, the nearby ICI explosives factory in Deer Park). This was the site of Australia’s first explosives manufactory, started in the 1870s by Jones Scott & Co, later operating as Australian Lithofracteur (Krebbs Patent), Australian Explosives and Chemical Co. and then in the 1890s, it was absorbed under Nobel’s Dynamite Trust in the 1890s. In 1927 Nobel’s and several other explosives and chemical companies worldwide formed Imperial Chemical Industries (ICI) with the local subsidiary becoming ICIANZ (Imperial Chemical Industries of Australia and New Zealand). However, it was still known as Nobel’s well into the second half of the twentieth century.

During and following World War Two, Albion was the major producer of Australia’s TNT and cordite. Additional facilities were progressively added, including DNT, a range of propellants and RDX (Research Department Explosives, as it was called by manufacturers t Woolwich arsenal. The fuse section initially relied on admixtures of traditional gunpowder, modified for controlled burning rates.

In 1937, ICIANZ decided to build Australia’s first plants to manufacture synthetic ammonia. They also built a plant for the oxidation of the ammonia, to produce nitric acid for the manufacture of commercial explosives. With the coming of the War in 1939, this decision suddenly became far sighted, as most raw material for nitric acid manufacture came from South America. The plant at Deer Park commenced manufacture in 1940, but in the event the bulk of nitrates used during the War did in fact come from overseas – in spite of the fact that ICIANZ built four more synthetic ammonia plants for the Federal Government between 1940 and 1945 in various parts of NSW and Victoria. Methanol was produced by somewhat similar high-pressure technology

Products in the black powder area (located on the western edge of the site) included smokeless fuse powder (black powder), RD 202, Ballistite, nitrocellulose (N.C. Y), and Carbamite. Fuse powder is an intimate mixture of charcoal, potassium nitrate and sulphur, known to both eastern and western civilisation for over 500 years. RD 202 is an intimate mixture of charcoal and ammonium perchlorate.

Each of these explosives required the incorporation of the ingredients as the main manufacturing process. This was achieved by the use of an edge runner or ‘Chilean Mill’ in which heavy rollers turning slowly on a horizontal axis rotate in a bowl providing a crushing and shearing force, without the shock of earlier processes such as the “Stamp Mill”.

Other processes which were represented by their own buildings at Albion were the charcoal house where specially selected timbers were burnt in retorts, the press house, where layers of mixed and crushed gunpowder were pressed into a cake on an hydraulic press, the breaking down house, where this cake was broken up, the corning house where the broken cake was fed through rollers to be crushed further and then sieved into various sizes, and the glazing house where the pellets of powder were given a polished finish.

Following the war, the factory was controlled from the Maribyrnong Explosives Factory, but continued to be upgraded, with the doubling of the available land in 1949, principally to accommodate the new RDX plant, built north of Furlong Road in 1957. The Albion and Maribyrnong Explosives Factories were amalgamated in 1976 and continued in operation until 1987, when most production ceased at Albion, and explosives manufacture was centralised at Mulwala. The Mulwala factory was established during the war using American technology obtained under the lend lease program.

Manufacture of NCY and Ballistite was discontinued and the area closed down before the war ended. In the mid 1960s most of the buildings had been removed. This was done by demolishing the timber structures and burning. By the 1980s, only the Black Powder mill and ancillary buildings along Station Road remained of the black powder area. These included offices, stores, laboratory, change rooms, mess room and charcoal preparation house. One of these buildings was used by the local scout group and another by the local amateur theatre aptly named the ‘Powderkeg Players’. The duplication of Station Road accommodated some of these buildings by leaving them in the middle of a very wide median strip (also to retain the sugar gum plantation).

From 1988 a program of decommission and demolition of buildings was begun, picking up in about 1998 when much of the site was cleared. By mid 2000, almost all the buildings had been demolished and a major program of decontamination was underway. The black powder mill is the last building to remain standing of the former 700-odd which once comprised the Albion Explosives Factory.

BLACK POWDER MILL - Assessment Against Criteria

Criterion A

The historical importance, association with or relationship to Victoria's history of the place or object.

The Black Powder Mill is a rare survivor of the Albion Explosives Factory, built as an annexe to the nearby ICI factory during the Second World War. As such it is a manifestation of Australia's approach to munitions production in wartime.Criterion B

The importance of a place or object in demonstrating rarity or uniqueness.

The Black Powder Mill is a rare example of a building type. It shaped concrete walls were designed to deflect the blast of a possible accident away from other buildings and over the creek.Criterion C

The place or object's potential to educate, illustrate or provide further scientific investigation in relation to Victoria's cultural heritage.

The Black Powder Mill is easily capable of interpretation, adding to an understanding of the dangerous nature of munitions production.Criterion D

The importance of a place or object in exhibiting the principal characteristics or the representative nature of a place or object as part of a class or type of places or objects.

The Black Powder Mill's design, while unusual in some respects, exhibits many of the broad characteristics typical of buildings used for munitions production. Safety for the operators and for nearby buildings is built into the design. The tool shadow board is typical of the type, as is the combination of massive and flimsy elements to control the direction of a possible blast.Criterion E

The importance of the place or object in exhibiting good design or aesthetic characteristics and/or in exhibiting a richness, diversity or unusual integration of features.

Criterion F

The importance of the place or object in demonstrating or being associated with scientific or technical innovations or achievements.Criterion G

The importance of the place or object in demonstrating social or cultural associations.

Criterion H

Any other matter which the Council considers relevant to the determination of cultural heritage significanceBLACK POWDER MILL - Permit Exemptions

General Exemptions:General exemptions apply to all places and objects included in the Victorian Heritage Register (VHR). General exemptions have been designed to allow everyday activities, maintenance and changes to your property, which don’t harm its cultural heritage significance, to proceed without the need to obtain approvals under the Heritage Act 2017.Places of worship: In some circumstances, you can alter a place of worship to accommodate religious practices without a permit, but you must notify the Executive Director of Heritage Victoria before you start the works or activities at least 20 business days before the works or activities are to commence.Subdivision/consolidation: Permit exemptions exist for some subdivisions and consolidations. If the subdivision or consolidation is in accordance with a planning permit granted under Part 4 of the Planning and Environment Act 1987 and the application for the planning permit was referred to the Executive Director of Heritage Victoria as a determining referral authority, a permit is not required.Specific exemptions may also apply to your registered place or object. If applicable, these are listed below. Specific exemptions are tailored to the conservation and management needs of an individual registered place or object and set out works and activities that are exempt from the requirements of a permit. Specific exemptions prevail if they conflict with general exemptions. Find out more about heritage permit exemptions here.Specific Exemptions:General Conditions: 1. All exempted alterations are to be planned and carried out in a manner which prevents damage to the fabric of the registered place or object. General Conditions: 2. Should it become apparent during further inspection or the carrying out of alterations that original or previously hidden or inaccessible details of the place or object are revealed which relate to the significance of the place or object, then the exemption covering such alteration shall cease and the Executive Director shall be notified as soon as possible. General Conditions: 3. If there is a conservation policy and plan approved by the Executive Director, all works shall be in accordance with it. General Conditions: 4. Nothing in this declaration prevents the Executive Director from amending or rescinding all or any of the permit exemptions. General Conditions: 5. Nothing in this declaration exempts owners or their agents from the responsibility to seek relevant planning or building permits from the responsible authority where applicable.* minor repairs and maintenance which replace like with like except that all effort should be made to retain original fabric wherever possible.

BLACK POWDER MILL - Permit Exemption Policy

The main importance of the Black Powder Mill lies in is its ability to demonstrate the function and inherent danger of grinding the components of gunpowder. Every effort should be made to retain the machinery and the tool shadow board in situ. Security from vandalism could be an issue and so works which reduce this risk should be allowed so long as they make the minimum intrusion or impact commensurate with achieving this aim. The light timber framed wall was clad in the past with panelling which has been damaged. Replacement panelling may be stronger than the original (Masonite?) but should be attached to the interior side of the frame. The siting of the building is important and there should be no development permitted between the building and the creek. Interpretive material should be encouraged so long as interpretive panelsm, signs and such do not become intrusive.

-

-

-

-

-

ICI Housing Estate Precinct

Brimbank City

Brimbank City -

ICI Residential Precinct

Brimbank City

Brimbank City -

Mount Derrimut Homestead

National Trust

National Trust

-

1 Fordham Court

Yarra City

Yarra City -

10 Fordham Court

Yarra City

Yarra City

-

-