FORMER THOONA DAIRY AND BUTTER FACTORY

38 SARGEANT STREET THOONA, BENALLA RURAL CITY

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

What is significant?

The Thoona Dairy and Butter factory was established in 1889 as a co-operative venture. At this time the expansion of the dairying industry was being encouraged by the Government. After 1880 technological advances in the dairying industry gave rise to a rapid expansion in production and stabilising quality of products. These advances also caused the co-operative approach to dairying. Machines such as the milk separator and the refrigerator unit were instrumental in bringing about profound changes. In summary these were the pooling of milk supplied from the farm, the rapid and large scale processing of that milk into butter and cheese at one location and the ability to store and export a quality product.

How is it significant?

The Thoona Dairy and Butter factory site is of historical and scientific (technical) and archaeological importance to the State of Victoria.

Why is it significant?

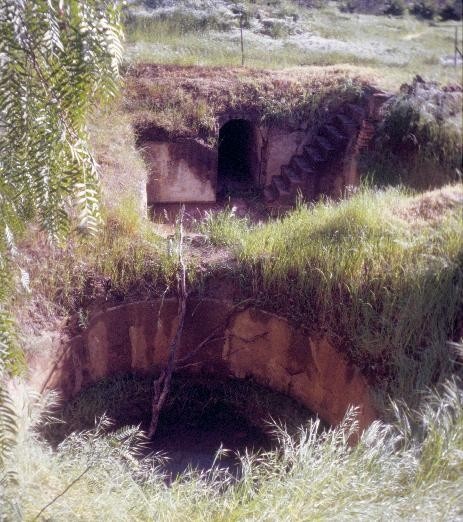

The Thoona Dairy and Butter factory site is important for its historical association with the rise of the dairying industry in Victoria and for its unique technical solution to the climate conditions of northern Victoria. The underground workings are rare in Victoria and the surviving ice-house structure is unique.

The Thoona Dairy and Butter factory site is important for its archaeological potential to reveal more information about this rare form of construction and the workings of this early dairying co-operative venture.

-

-

FORMER THOONA DAIRY AND BUTTER FACTORY - History

Contextual History:History of Place:

The Australian dairy industry began in c1820 in New South Wales, in the Illawarra area, just south of Sydney.

Geographical and climatic conditions determined the early settlement of dairying interests. Dairy cattle require a longer growing period for the herbage than sheep if they are to be maintained in peak condition. For this reason the early days saw the industry concentrated on the coastal plains. As forest areas were cleared and road and rail transport developed the dairy industry moved further inland.

The dairy industry was until the late 19th century a localised activity. Milking of cows and the processing of milk to cheese and butter was carried on at small holdings and usually by the farmer and his family. The co-operative approach to milking, butter and cheese making did not come into being until after about 1880 when inventions such as the separator, the Babcock milk test, and the progressive improvement on methods of mechanical refrigeration.

Co-operative ventures improved the quality and consistency of output and this was assisted by the combining of milk from the various herds in the co-operative. The in-flowing quantity made it worthwhile to purchase and use large size churning and separation equipment and to power this with steam engines and line shafts. The engines were also used to power refrigeration compressors .

The output was to be greater consistency in cheese, butter and milk. Governments were also instrumental in this capitalisation of the industry by paying a benefit for dairies which took in a daily standard capacity. Local councils also upgraded roads to dairies although in some cases the co-operative farmers took matters into their own hands and carried out the repairs themselves.

During the 1880s three significant developments improved the industry and allowed for rapid expansion. They were:-

(1) Refrigeration, particularly mechanical and portable refrigeration.

(2) The cream separator which did away with standing fresh milk for days until the cream rose to the surface of the milk.

(3) The Babcock Tester which enabled farmers to measure the amount of butter-fat in the milk yield.

Milking machines were introduced in 1896 but it wasn’t until the labour shortage caused by World War One that they became widely used.

The Separator

R.A. Lister in England produced the first milk separator filled with stainless steel discs The Lister separator could handle 60 gallons of milk an hour and produce a higher ratio of cream than using traditional methods. The first of these machines to be seen locally was at the 1886 Melbourne Show and cost fifty pounds each, without a motor. It took two men to lift the bowl alone.

The De Laval separator patented in 1878 was to have a widespread and profound impact on the industry. It operated at up to 1800 rpm and was steam driven. By 1891 there were 445 separators in Victoria, one for every 887 cows. By 1901 this had grown to 41,131 separators, one for every 26 cows. Almost every dairy had one. The separator was one of the primary motivational forces in the co-operative approach to dairying as it:

? could separate large quantities of milk

? reduced the processing time thereby reducing the effects of harmful microbes on the milk

? could be used continuously

? could be mechanically powered.

The larger the separator purchased the higher the throughput but also the higher the cost and the greater the motive steam force required to drive it.

Babcock Test

The Babcock test patented by American S.M. Babcock in 1890 allowed the fat content of milk to be rapidly tested. The Koroit and Tower Hill dairy initiated the Australian butter fat economy by buying milk supplies based on fat content in November 1892.

Refrigeration

The preservation of foods has always been of primary interest to humans. Prior to medieval times seasonal foods were eaten and storing of foods was not feasible in most cases. Although there have been traces of the use of icehouses in medieval times, it wasn’t until early in the 17th century, in Europe and later Britain, that they became quite widely used. At this time the use of ice from icehouses was primarily to allow for the cooling of desserts during warmer weather. People gradually came to realise that ice could be used for a wide variety of purposes. Ice was collected in winter time from frozen lakes and streams. It was cut into blocks, packed in straw and transported to ice houses for long term storage. It would slowly melt in the ice houses and they therefore required appropriate drainage. Early purpose built houses were designed by architects such as John Papworth who gave requirements thus: in a retired spot in the grounds, and not far removed from water, and yet sufficiently elevated to be removed from damp. Between 1750 and 1875 some three thousand ice houses were built in Britain with a large number of these in the grounds of country houses .

The world’s first ice making works were established in Geelong in 1851 by James Harrison but it took until the 1880s to resolve a reliable process of refrigeration.

It seems natural then for the diary co-operative such as the one at Thoona to resort to the use of an ice house prior to the advent of reliable cool rooms. Cool rooms were an important storage facility at any dairy as it had been discovered that the process of decay by microbiological agents was slowed by the cooler temperatures.

History of the Thoona Dairy

The decision to build a butter factory at Thoona was made in March 1889. The initial idea had been discussed in February of the same year. The first building used was one owned by Mrs Warrington, of the Commercial Hotel. A De Laval separator (largest size), a Bartram’s Box Churn, a Cherry’s Patent butter worker and a Clayton and Shuttleworth five horse-power engine were the first pieces of equipment used at the factory when it opened in mid April.

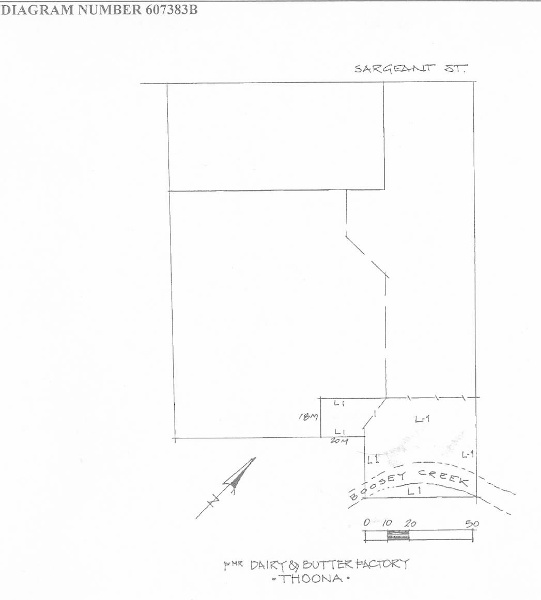

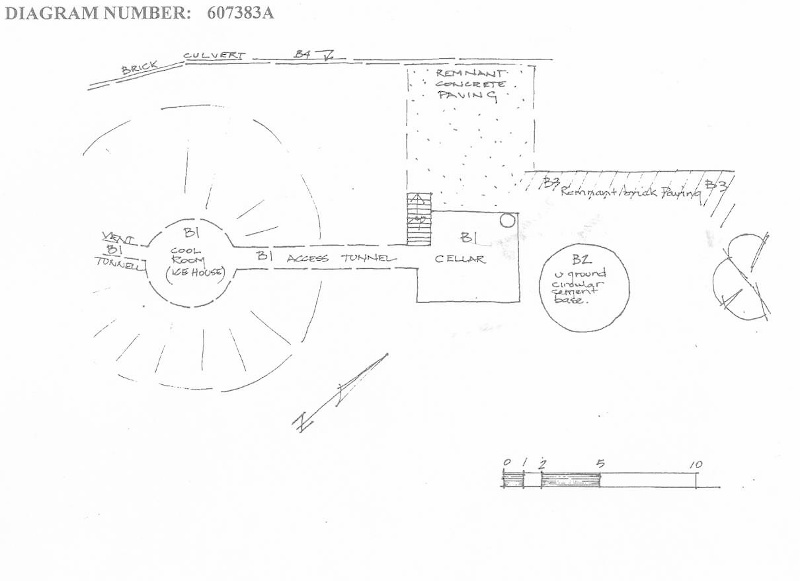

The permanent factory building was begun on a site in Sargeant St., Thoona, where what remains of it can be seen today. It was built on an acre of land purchased from Mr Sergeant for £20 pounds, on the banks of the creek, 20 chains from the township. Building started in the first half of 1889 and the factory was opened for business in August of that year. The underground rooms of the factory consisted of a cellar and cool-room (or two coolrooms), both 10x10 feet, connected by a tunnel. The first cool-room was accessed from above by eleven steps. It appears that ice was used in these cool-rooms, similar to the method used in icehouses. Two underground tanks supplied ample water for the factory. These were roofed with a hipped roof structure.

There were also working areas above ground as seen in a photograph of the factory in The History of Thoona . The above ground structure was 35x 20 feet, built of timber with a seven foot wide verandah all round.

The purchase of a second De Laval separator allowed the milk to be run through in half the time and allowed the workers to complete their work with much more ease.

By September of that first year the factory was becoming an important part of the local dairy industry, as reported in the local newspaper.

The spring in the grass has caused a great rise in the quantity of the milk at Thoona Butter Factory. There are three or four more producers since the beginning of the month and the weekly supply is about 3800 gallons. About 270lbs of butter is made daily which will be largely increased as the season advances. The Manager intends to have an exhibition at the Wangaratta Show.

By November 1889, a large fan had been procured and set up in the butter room. It was driven by the engine and the temperature in the room was brought down considerably. The daily milk supply had reached 1000 gallons and 15 cwt of butter was sent “home” to England as a trial to test the market.

Butter sent to the Department of Agriculture at Newport, where it is frozen (takes 7-8 days) then shipped at Williamstown by the Orient Shipping Coy., the only one with cool chambers on all it’s ships. Can ship only during three months (from October). Sent to an agent in London. The advantage of sending butter “home” during this time is the shortage there during the Winter months and the glut here, thus giving two markets.FORMER THOONA DAIRY AND BUTTER FACTORY - Permit Exemptions

General Exemptions:General exemptions apply to all places and objects included in the Victorian Heritage Register (VHR). General exemptions have been designed to allow everyday activities, maintenance and changes to your property, which don’t harm its cultural heritage significance, to proceed without the need to obtain approvals under the Heritage Act 2017.Places of worship: In some circumstances, you can alter a place of worship to accommodate religious practices without a permit, but you must notify the Executive Director of Heritage Victoria before you start the works or activities at least 20 business days before the works or activities are to commence.Subdivision/consolidation: Permit exemptions exist for some subdivisions and consolidations. If the subdivision or consolidation is in accordance with a planning permit granted under Part 4 of the Planning and Environment Act 1987 and the application for the planning permit was referred to the Executive Director of Heritage Victoria as a determining referral authority, a permit is not required.Specific exemptions may also apply to your registered place or object. If applicable, these are listed below. Specific exemptions are tailored to the conservation and management needs of an individual registered place or object and set out works and activities that are exempt from the requirements of a permit. Specific exemptions prevail if they conflict with general exemptions. Find out more about heritage permit exemptions here.Specific Exemptions:Nil

-

-

-

-

-

Thoona Military Reserve

Vic. War Heritage Inventory

Vic. War Heritage Inventory -

Thoona Honour Roll

Vic. War Heritage Inventory

Vic. War Heritage Inventory -

Thoona School Honour Roll (First World War)

Vic. War Heritage Inventory

Vic. War Heritage Inventory

-

'Lawn House' (Former)

Hobsons Bay City

Hobsons Bay City -

1 Fairchild Street

Yarra City

Yarra City -

10 Richardson Street

Yarra City

Yarra City

-

-