WATER TOWER AND TANK

12 MILLARD STREET WANGARATTA, WANGARATTA RURAL CITY

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

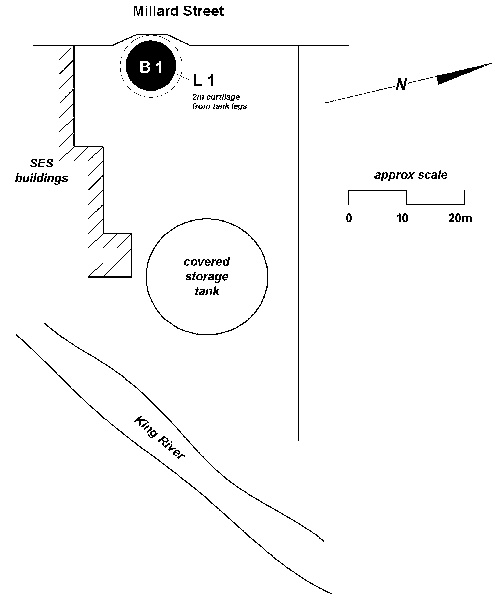

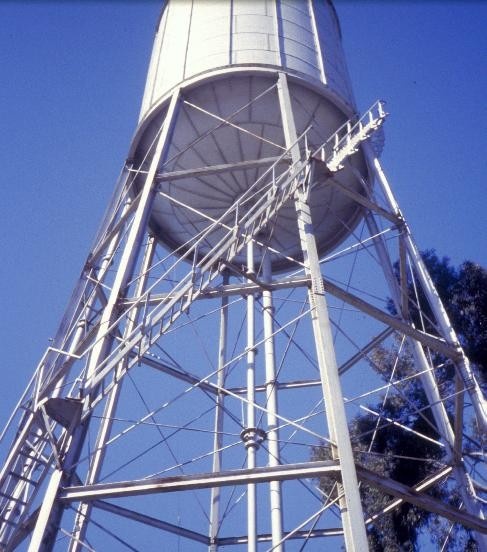

The Water Tower and Tank at 12 Millard Street Wangaratta consists of a tank constructed of curved steel plates tightly rivetted together to make waterproof joints, on a tower of eight splayed rolled steel joist legs carrying the unusual steel maker's brand of "A.H.A.V.". There is spiral steel access ladder. The structure, which was intended to improve reliability and pressure of the water supply, was built in 1903 to the design of Euroa engineer WC Howitt. The steel for the structure was fabricated and erected by the firm of A. Challingsworth of Richmond. The structure receives water directly from the King River. The original steam pump was replaced in 1930 by electric power.

The Water Tower and Tank at 12 Millard Street Wangaratta is historically and scientifically (technologically) significant to the State of Victoria.

The Water Tower and Tank at 12 Millard Street Wangaratta is of historical and scientific (technologocal) significance for its early (1903) use of rivetted and rolled steel in this application and effectively demonstrates the technological change from the use of wrought iron or cast iron (materials of the 19th century), to steel (one of the main construction materials of the 20th century) and is one of only a handful of surviving all-steel water tanks and towers in Australia from this period. The steel legs of the tower were made from a rare early brand of rolled steel.

The water tower is of historical significance as an important landmark in Wangaratta. It is of interest for its association with Mrs Challingsworth who for many years in the late nineteenth and early twentieth centuries managed the firm of her late husband in an industry traditionally dominated by men.

-

-

WATER TOWER AND TANK - History

Source: C. & M.J Doring Pty. Ltd. Millard Street Water Tower Wangaratta Heritage Report March 1999

Like most early towns, Wangaratta was founded close to a source of fresh water - in this case close to the junction of the Ovens and King Rivers. As the town spread further from the rivers, water carting became a thriving business. In 1871 the Wangaratta Borough Council appointed a committee to investigate a way of providing a reticulated water supply. The railway from Melbourne to Wodonga via Wangaratta was being built at that time, and would need water for the steam locomotives. It was agreed in 1873 that the Railways would build and operate a steam-driven pumping station at Millard Street, and a water tower at Wangaratta Station, to provide water for both the Railway and the town. The Council would install the distribution pipes, plus contribute £1500 to the cost of the pumps and tower, and would pay a further 1 shilling per 1 000 gallons delivered to the town. (Unless attributed otherwise, historical details in this section are derived from ‘Wangaratta’, the history of the town written by D.M. Whittaker. This valuable secondary sources is based on, and extensively quotes, council minutes and contemporary newspapers.)

There were many complaints about the inadequacy of the supply from the Railways, and in 1894/5 the Council took over the existing supply system, and on the advice of the state Department of Water Supply (DWS) they installed a new steam-driven pump at Millard Street. To maintain constant pressure the system still relied on the c.1874 Railways water tower, a circular iron 40,000 gallon tank on a tall circular brick tower (still standing near the station in 1999, but now disused). The new plant was intended to provide 16 million gallons per year, a quarter of which was to be bought by the Railways but at about half the price they had previously charged the Council.

The new system must still have been inadequate, because in September 1901 the Council engaged private consulting engineer Mr. W.C. Howitt of Euroa to advise on improving the supply. He seems to have conducted a thorough survey, considering possible pumping stations drawing from the King River (at Millard Street) or from the Ovens River (probably near the present Faithfull Street treatment works)., but also considering non-pumped gravity supply from high ground in the Warby Ranges, or from the upper King River. In October he reported that only the King River would give a reliable and clean supply. (This was at the time of extensive gold mining and sluicing in the Ovens catchment.)

Howitt offered two alternatives. Council could install another new pump and a new water tower at Millard Street, or build a long pipeline bringing water under gravity pressure from the upper King River at Edi or Whitfield - where the water would be cleaner than in the river at Millard Street. Howitt favoured the gravity pipeline, which would cost more initially but would save pumping costs and would be cheaper in the long run. Some councillors, including Mayor Allan, agreed with Howitt, but the majority preferred the option of a new pump and water tower at Millard Street, because the lower initial cost would avoid having to increase property rates to repay a large loan (Wangaratta Chronicle, 4 Sep 1901 & 12 Oct 1901).

Council warmly thanked Mr Howitt for his report, but decided to refer the alternative schemes to DWS for comment before making a decision. The Chronicle editor described the alternatives in some detail, and gave tacit support to the gravity scheme, but endorsed Council's decision to refer the matter to DWS for advice .(Wangaratta Chronicle 12 Oct 1901 & 4 Dec 1901). Mr Thomas Murray, engineer from DWS visited Wangaratta to investigate the alternative schemes in January 1902, but it was not until 28th July 1902 that Council received his report. At a special meeting on 19th August, Council considered Murray's report and decided to drop the gravity scheme and go ahead with a new pump and water tower at Millard Street, but not to build the proposed filter beds. Council also instructed Mr. Howitt to prepare detailed plans and specifications for the new water tower, pumping machinery, etc (Council Minutes, 28 Jul 1902 & 19 Aug 1902. Wangaratta Chronicle 30 Jul 1902)

In September 1902 the Council advertised that they had applied to the Minister for Water Supply for a loan of £11,000 to build the new pump, water tower and reticulation pipes in accordance with plans supplied to DWS, and asked for a Waterworks Trust to be established to manage the works and the funds. However, DWS advised that their loan application was late, and that at most only £2,000 or £3,000 would be made available this year, for erecting the water tower. Council immediately asked Mr Howitt to call tenders for the erection of the water tower (Wangaratta Chronicle, 3 Sep, 10 Sep & 22 Oct 1902. The plans supplied to DWS possibly still exist at Public Records Office, but have not been researched for this report.).

Mr Howitt called tenders for a 90,000 gallon tank, upgraded from 80,000 gallons at DWS request. During the tender process the DWS requested further minor changes, which Howitt decided to handle as negotiated extras, rather than call fresh tenders. After some debate, Council decided at a meeting on 17th November to open the six tenders, even though the £2000 loan had not yet been approved (Wangaratta Chronicle, 5 Nov & 19 Nov 1902). Two of the contractors declined to bid, and four companies submitted firm bids, namely:

Johnston & Sons: £2515

W. Farquarson: £2388

Dorman, Long & Co.: £2200

A. Challingsworth: £1859.

Council again deferred a decision, pending further negotiations with the DWS about the loan, which was several times promised and then withdrawn. On 12th December 1902, Mayor Pinkerton reported that the DWS had confirmed that a loan of £2000 would be available, thanks to the intervention of a Mr Bowser MP. Council at last accepted the Challingsworth tender of £1859, but instructed Mr Howitt to negotiate with Mrs. Challingsworth about the cost of extra modifications required by DWS.

At about the same time, the old pumping station boiler broke down, and had to be urgently replaced (according to Council Minutes of 1 Dec 1902), or repaired (according to Minutes of 2 Dec 1902).

There were still problems in verifying the £2000 loan from DWS, but Council obtained temporary bank finance, and let the contract for the new water tower. On 12 January 1903, Mr Howitt reported that the DWS modifications would cost about £ 100 extra (actually £97), and that Mrs. Challingsworth would begin fabricating the steelwork for the tank and its tower after the New Year Holidays. The foundations for the tower would be dug out and concrete poured at about the end of January (Wangaratta Dispatch, 14 Jan 1903).

In March 1903 the Council authorised Mr. Howitt to engage a Clerk of Works to oversight the contractor's work of erecting the tower and tank at the Millard Street site. Transporting the tank to Wangaratta, erecting the steel tower, then putting the tank on top must have been quite a feat in those days, when you could not just ring up and hire a large mobile crane or "cherry-picker", but had to rely on primitive sheerleg cranes, wooden scaffolding, winches, ropes and pulleys, etc..

There was a small problem in April when the DWS complained that Mr. Howitt had authorised alterations to the design of the tower without DWS approval. However, Howitt explained that this involved a minor change from uniform to non-uniform vertical spacing of the tower's horizontal bracing, to avoid a clash between construction joints in the horizontal and vertical members, and that the changes made the tower stronger than the original design. Despite their obvious annoyance, the DWS engineers had to agree that the changes were safe, but warned Howitt not to make further changes without DWS approval (Council Minutes, 23 Mar 1903, 6 Apr 1903. Wangaratta Dispatch, 8 Apr 1903).

In July 1903 the Secretary for Mines and Water Supply acknowledged that Council had applied for formation of a Water Trust, and for a loan of £1 1,000, being £4000 to take over existing liabilities, and £7000 for new works (ie. the new pump and new water mains). The Secretary advised that the request was received favourably, and that the £2000 government loan to replace Council's bank loan would definitely be approved in the next session of parliament. In August, Mr Howitt advised Council that he had seen a list of monies to be voted in next parliamentary session, including £7000 for Wangaratta, and that therefore work on the new pump etc., should be able to begin in two or three months time (Wangaratta Dispatch, 8 Jul 1903 & 12 Aug 1903).

Late in August 1903, Mr Howitt advised Council that the new water tower was erected and had been in the process of being filled under test when the [cl 895?] pump broke down after putting only 3 feet (1 metre) of water into the tank. This exposed some minor leaks in the tank which were being caulked by hammer and chisel. Parts of the large pumping engine [indicating there were at least two pumps then] were sent to Melbourne for repair, and meanwhile the contractor's men were waiting to finish the tests. Howitt also recommended that design and specifications for the new pump, mains etc., be prepared and approved soon, to minimise delays once the loan money came through (Wangaratta Dispatch, 26 Aug 1903).

The date of completion of the new water tower is not clear, but appears to have been sometime in September or October 1903. It must have been before November 1903, when Mr. Howitt submitted his account for £106. This was made up of £99 for professional engineering fees, being 5% of the tower contract cost of £ 1986, plus a further £7 for travel expenses in visiting Melbourne contractors and the DWS. By February 1904 the new water tower had been inspected and approved by two engineers from DWS, and both Mr. Howitt and Mrs. Challingsworth had received their final payments for the tower (Wangaratta Dispatch, 18 Nov 1903 & 2 Dec 1903).

Before leaving Mrs. Challingsworth, it is worth noting here some facts about her and her business. After arriving from England with his family in 1880, Mr. A. Challingsworth had established a gas appliance and steel fabrication business in Melbourne, variously described as being in the suburb of Burnley or Richmond. (Small cast-iron plaques on the Millard Street water tower say "A. CHALLINGSWORTH, Maker, East Richmond".) The business was taken over by Mrs Challingsworth in 1888 when her husband died. The exchange of letters between the Council and Mrs. Challingsworth, and Mr. Howitt's ongoing negotiations with her, indicate that she was definitely the active manager of the business, not just the owner. It was most unusual for a woman to run that type of business at that time, and it is still uncommon today. Mrs. Challingsworth must have managed it well. The Millard Street contract seems to have been handled efficiently, and the business was still operating at 476 Swan Street, Richmond in 1945 (The Australasian Manufacturers Directory, 1945. The Manufacturer Publishing Co. Pty Ltd., Sydney).

Having got their water tower built, it was not long before the Council got the go-ahead for the rest of the scheme. On 24th October 1904 the Wangaratta Waterworks Trust was officially constituted by government gazette, and just two days later a group of nine Commissioners (eight local councillors plus one government nominee) met as the Trust, with Mr Howitt also present, and considered tenders for several major elements of the new works. (Obviously the specifications must have been prepared and tenders called prior to the Trust being established.) The Trust sought advice from DWS on some of the tenders, and made their final decision on the tenders at a meeting on 31st October (Wangaratta Dispatch, 26 Oct 1904 & 31 Oct 1904).

The tenders received are listed below. The successful tenderers, who carried out the work, are marked with an asterisk:

(a) Tenders for pumping station building and pump well:

* A. Hancey £248

C.N. Daly £272

Gray Bros. £273.

(b) Tenders for supply of cast-iron pipes:

Austral Otis Co. Ltd. £2214,

* Monteith & Sons £2075,

Mephan Ferguson £2146.

(c) Tenders for supply of galvanised iron pipes;

* Richard Linton £224,

Stewart & Lloyd Ltd. £235,

John Danks & Son £248,

T. McPherson & Sons £237.

(d) Tenders for supply and installation of the steam engine and pumping plant:

Bennie, Teare & Co, £995 (and £79 extra if they put in the foundations),

Johnson & Sons £688,

Hanson & Halliday £848,

Austral Otis & Co. £ 1395 or £ 1375 in alternative tenders,

* Welch Perrin & Co. £781 or £855 in alternative tenders. (£855 bid accepted)

(e) Tender for carting of pipes:

* Perinewan Wright & Co. £45 (others not given).

(f) Tender for yarn and packing:

* W.L. Thompson, £ 15 (others not given).

Mr. Howitt said the new pumping plant would raise four times the water of the present plant, and would use less wood to fire the boilers. The reasons for choosing Welch, Perrin & Co., over the other tenderers for the pumping plant were:-

Bennie Teare & Co. £995, was for a gas engine, so not suitable.

Johnstone & Sons £688, was for a steam plant without compound cylinders or condenser, and so would be extravagant on fuel.

Hampson & Halliday, £848, was for compound cylinders but no condenser.

The other tenders all offered engines with compound cylinders and condensers, but at widely different prices.

The Welch, Perrin tender for £855 was accepted because it offered an engine as good

as the others, at less cost.

[Compound steam engines had two or three progressively larger cylinders in which the steam expanded in two or three stages, from high pressure to intermediate to low pressure. This gave a more efficient extraction of the steam's energy than the early single-cylinder engines. Condensers were separate watercooled chambers in which the exhausted steam was condensed back to water, which increased the pressure drop through the engine and increased engine speed, and so again increased engine efficiency. The condensate also provided pure distilled water to be fed back into the boiler.]

In December 1904 Howitt reported that excavation of the pumping house site was nearly complete, and the new boiler was expected soon. Pipe laying was underway, but had been delayed by slow delivery of the cast-iron pipes. In January 1905, the boiler was being bricked into place, and most of the 9 inch diameter water main pipes had been laid, but the engine house and pump well were still not finished and this had delayed installation of the pumping engine (Wangaratta Dispatch, 14 Dec 1904 & 25 Jan 1905. Wangaratta Chronicle, 11 Jan 1905).

By February 1905, Monteith & Sons had delivered all the cast-iron pipes, and wanted final payment. The 8 inch and 7 inch main pipes were being laid, and old 4 inch mains removed. Howitt reported that under threat of having his contract cancelled, Mr Hancey was now progressing with the pump building and the pump-well. By 20th March Howitt reported that the water tank had been painted inside, the pump building was complete, the pumping engine was installed and it would be connected to the tank and given a test run in the next week. By 17th April 1905, Howitt was able to report that the plant had been in operation for the past fortnight, and that some of the intake and outlet pipework needed to be altered, but otherwise the plant was satisfactory.

However, relations between the Trust and Mr. Howitt, which had been very good, were now turning sour. Howitt was criticised by some of the Waterworks Trust councillors for installing the intake pipe too high, so that it would be exposed if the river level dropped, as it had done the previous summer. He was also criticised for visiting Wangaratta to inspect the work only about once per fortnight, instead of twice per week as promised. There were also many disputes with contractors about progress payments and claims for extras not being paid by Council, or not authorised by Mr. Howitt, and about local workmen and subcontractors not being paid by the building contractor Mr. Hancey (Wangaratta Dispatch, 22 Feb 1905. Wangaratta Chronicle, 22 Feb 1905, 22 Mar 1905 & 19 April 1905).

Things came to a head in May, after the pumping engine contractor Welch, Perrin & Co. sent a letter stating they had completed the installation and run the engine for a satisfactory two week trial, and asked for payment of £855 contract price plus £50 extras, total £945, less £500 already paid. The Trust members asked to witness another test run, which did not go well. With the pumping engine running at maximum speed of 84 strokes per minute, and at maximum steam pressure of 123 psi (pounds per square inch), it managed to deliver only 38,000 instead of the specified 45,000 gallons per hour.

The Trust was not happy, and one particular councillor, who had long been critical of Mr Howitt, made scathing remarks questioning his competence in approving the pump, and proposed that the Trust should refuse to pay his fees. Mr Howitt in return got very annoyed and told the Trust they had no business questioning his competence or judgement as an engineer, that he and two DWS engineers had together witnessed very satisfactory tests of the pumping engine, and that subject to the contractor carrying out some minor modifications he would sign the certificate of acceptance and authorise payment (Wangaratta Chronicle, 10 May 1905).

Mr. A.S. Kenyon, engineer for DWS, agreed to arbitrate by supervising a further test run to be witnessed by various Trust commissioners (councillors), by Mr. Howitt, and by Mr. M.S. Smith representing the pump contractors Welch, Perrin & Co.. The contractor provided the machine operator, who discovered that the previous operator (also supplied by the contractor), had left open a valve which should have been closed. [This was probably a bypass valve allowing outlet water to flow back to the river at zero pressure, so the pumping engine could be started easily under no load.] With the valve closed, the pump worked well, as the Chronicle reported:

"In the hands of the experts yesterday the pump worked with great smoothness and easily raised 52,000 gallons an hour. In the presence of the [Trust] Commissioners, who checked the figures, the pump raised 38,000 gallons an hour when working at what might be termed its ordinary rate of42 strokes per minute, 49,000 [gph] at 52 strokes, and 56,000 an hour at 58 strokes to the minute. [This compares with 38,000 gph at 84 rpm under the previous test.] The Commissioners expressed entire approval of the plant in view of the convincing result of the test, and acknowledged the courtesy of Mr. Kenyon in connection with the further test." [There was no mention of an apology to Mr. Howitt.] (Wangaratta Chronicle, 24 May 1905)

Once the pumping engine had been accepted, most of the physical work on the new waterworks was completed, although there was ongoing work to connect users to the new mains, and to connect the old railways water tower to the new system for Railways use. The latter was partly paid for by the Trust, because the old tower would also help maintain service pressure in the western parts of the town. At the suggestion of Mr. Fraser, the Trust's plant operator, the old pumps were cleaned and oiled to keep them in good condition as an emergency back-up. Disputes and negotiations over Payments to the contractors and to Mr. Howitt dragged on for months, but there is no need to detail those here (Wangaratta Chronicle, in various issues from May to October 1905, and possibly beyond).

In 1929 the Woollen Mills built its own power house, providing electricity to the mill and to the town. The Waterworks Trust considered changing to electric pumps, but the existing steam-driven pumps were working well, and were retained then. However, in 1927 the State Electricity Commission started supplying Wangaratta, including the mills, and in 1929/30 the Trust changed to electric pumps powered by the SEC. Presumably the steam pumps were removed at about the same time.

The old Railways water tower was proving inadequate for the growing demand, and in 1923 the Trust had a 105 feet tall concrete water tower (about 34 metres) built at the western end of Docker Street, adjacent to the railway line. However, it was poorly built, and developed leaks and a slight lean. While the Trust and the contractor were still arguing over what to do, the tower collapsed on 5th April 1905, fortunately causing relatively little damage and no injuries. New engineers and contractors were engaged by the Trust, and a new concrete water tower was built on the same site. It was completed in 1929, and served for many years. That tower is still standing today, but is now disused (except for activities such as abseiling). Another concrete water tower was erected later at Kerr Street c.1950, and that remains in use today (but may also be made redundant by the new constant-pressure pumps).

During a series of dry years in the 1920s, 30s and 40s, when the King River at Wangaratta got very low or even ceased to flow, there were several attempts to improve the town supply by building a gravity pipeline from the upper King River, as proposed by Mr. Howitt in 1901, and by George Maxwell, surveyor, in 1890. However, the cost of such schemes stopped that idea from being implemented. Trial bores were drilled near the town in 1937/38, and a borewater filtration plant built next to the bridge over the Ovens River. Despite poor flows and high costs, further bores were drilled and this became a major source of town water for about ten years.

In 1944 additional supply was obtained by temporarily relocating one of the King River pumps to the Ovens River, and directly pumping into the borewater filtration plant. This was successful, and a permanent Ovens River pumping station and larger filtration plant were built in 1946/49. Whether the Ovens water was at last able to be used because it was less contaminated than in earlier years, or because filtration technology had improved, or because it had always been good enough to use, is not clear.

Whatever the reason, since the 1940s Wangaratta has continued to pump water from the Ovens River just above the main road bridge, filter the water at the Faithfull Street plant, and distribute it by underground pipes from there. The Millard Street and Kerr Street water towers remain in use to help maintain pipe pressure in the southern and western parts of town, assisted by local booster pumps.

In 1994, the assets and responsibilities of the Wangaratta Water(works) Trust were handed over to the Ovens Water Authority, which in 1997 was itself amalgamated into the larger North Eastern Region Water Authority, based in Wodonga. The NERWA continues to operate the Wangaratta water supply, but is planning some changes. In particular, the NERWA currently (1999) proposes to install new variable-speed electric pumps which will maintain constant pressure without the need for water towers, making the existing towers redundant.WATER TOWER AND TANK - Assessment Against Criteria

Criterion A

The historical importance, association with or relationship to Victoria's history of the place or object.

The Millard Street water tower represents the first and most visible element in the programme of the Wangaratta Council and Waterworks Trust, to make a major improvement to the quality, extent and reliability of the town's water supply at the start of the 20th century.

Criterion B

The importance of a place or object in demonstrating rarity or uniqueness.

It is one of the very few surviving all-steel water tanks and towers in Australia, of this great age. The steel legs of the tower were made from a rare early brand of rolled steel.

Criterion C

The place or object's potential to educate, illustrate or provide further scientific investigation in relation to Victoria's cultural heritage.

Criterion D

The importance of a place or object in exhibiting the principal characteristics or the representative nature of a place or object as part of a class or type of places or objects.

It demonstrates the technological change from the use of wrought iron or cast iron (materials of the 19th century), to steel (one of the main construction materials of the 20th century).

Criterion E

The importance of the place or object in exhibiting good design or aesthetic characteristics and/or in exhibiting a richness, diversity or unusual integration of features.

Criterion F

The importance of the place or object in demonstrating or being associated with scientific or technical innovations or achievements.

Criterion G

The importance of the place or object in demonstrating social or cultural associations.

It is associated with Mrs. Challingsworth, a most remarkable woman who more than a century ago took over and successfully managed a prominent company in the then exclusively masculine business of heavy steel fabrication.

Criterion H

Any other matter which the Council considers relevant to the determination of cultural heritage significanceWATER TOWER AND TANK - Permit Exemptions

General Exemptions:General exemptions apply to all places and objects included in the Victorian Heritage Register (VHR). General exemptions have been designed to allow everyday activities, maintenance and changes to your property, which don’t harm its cultural heritage significance, to proceed without the need to obtain approvals under the Heritage Act 2017.Places of worship: In some circumstances, you can alter a place of worship to accommodate religious practices without a permit, but you must notify the Executive Director of Heritage Victoria before you start the works or activities at least 20 business days before the works or activities are to commence.Subdivision/consolidation: Permit exemptions exist for some subdivisions and consolidations. If the subdivision or consolidation is in accordance with a planning permit granted under Part 4 of the Planning and Environment Act 1987 and the application for the planning permit was referred to the Executive Director of Heritage Victoria as a determining referral authority, a permit is not required.Specific exemptions may also apply to your registered place or object. If applicable, these are listed below. Specific exemptions are tailored to the conservation and management needs of an individual registered place or object and set out works and activities that are exempt from the requirements of a permit. Specific exemptions prevail if they conflict with general exemptions. Find out more about heritage permit exemptions here.Specific Exemptions:General Conditions:

1. All alterations are to be planned and carried out in a manner which prevents damage to the fabric of the registered place or object.

2. Should it become apparent during further inspection or the carrying out of alterations that original or previously hidden or inaccessible details of the place or object are revealed which relate to the significance of the place or object, then the exemption covering such alteration shall cease and the Executive Director shall be notified as soon as possible.

3. If there is a conservation policy and plan approved by the Executive Director, all works shall be in accordance with it.

4. Nothing in this declaration prevents the Executive Director from amending or rescinding all or any of the permit exemptions.

5. Nothing in this declaration exempts owners or their agents from the responsibility to seek relevant planning or building permits from the responsible authority where applicable.

Exemptions

* Minor repairs and maintenance which replace like with like.

* Installation, repair or removal of antennae, aerials etc.

* Painting of previously painted surfaces provided that preparation or painting does not remove evidence of the original paint scheme.

* Emergency and safety repair works.

* Adaptation of the existing ladder to satisfy current safety regulations by closing in the open handrails with steel mesh or similar, and by fitting wider treads (and risers) to the existing narrow angle-iron treads in the upper portion, running around the side of the tank.

* Construction of a new ladder to modern standards provided it is bolted (not welded) to the structure and provided the old ladder is retained.

* Repairs and maintenance to waterworks infrastructure.

* Landscaping and garden works.WATER TOWER AND TANK - Permit Exemption Policy

Ideally, the Millard Street water tower should be kept in service as a working reservoir, in daily active use as a header tank, or as a back-up storage for short-term emergency supply if the pumps, filters or delivery mains fail. Ongoing use as a reservoir would retain the maximum heritage significance for the tower, and would help justify its maintenance costs. But if ongoing use of the Millard Street water tower to hold water is not possible, then it should be drained and left standing as a dry monument, as has been done with the Benalla water towers. This appears to require very little maintenance effort, and will at least retain the structure as an historic artefact and landmark.

-

-

-

-

-

WARRA

Victorian Heritage Register H0521

Victorian Heritage Register H0521 -

FORMER ANZ BANK

Victorian Heritage Register H0226

Victorian Heritage Register H0226 -

HOLY TRINITY ANGLICAN CATHEDRAL CLOSE

Victorian Heritage Register H1065

Victorian Heritage Register H1065

-

'Mororo' 13 Oxford Street, Malvern

Stonnington City

Stonnington City -

1 Arnold Street

Yarra City

Yarra City -

1 Austin Street

Yarra City

Yarra City

-

-