CASSILIS GOLD MINING COMPANY TREATMENT WORKS

BAYLISS SPUR ROAD SWIFTS CREEK, EAST GIPPSLAND SHIRE

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

What is significant?

The Cassilis GMC treatment works is in Power's Gully. It is the site of mining operations carried out from 1897 to 1916 and the elaborate plant and processes used to extract gold from heavily mineralised ore. Steam was first used to power the machinery at the site but a shortage - and consequent high cost - of firewood led to the company constructing a hydro-electric scheme. The power station operated from Victoria River. The scheme was completed in 1907, and by 1909 all steam engines had been replaced with electric motors. The significant visible components of the site include but are not limited to:

* Electricity substation.

* Loading ramp, which was fed by a tramway that runs around the spur to the mine workings.

* Battery foundations including mortar blocks and engine beds.

* Concrete vat piers and adjoining dump of treated battery sand.

* Brick and stone retaining wall.

* Brick and concrete-rendered vats and associated raised tailings pond.

* Riveted iron furnace lined with red fire bricks.

* Furnace bed.

* Remnant of large flue.

How is it significant?

The Cassilis GMC treatment works is of historical and scientific significance to the State of Victoria.

Why is it significant?

The Cassilis GMC treatment works is historically important as the largest and most successful mine to operate on the Cassilis field and due to its association with the construction of Victoria’s first gold related hydro-electric scheme. The power station was located 27kms away, near the Victoria Falls on the Cobungra River.

The Cassilis GMC treatment works is scientifically important for the survival of a range of relics documenting the transition from steam-power to electric-power. No other historic gold mine in Victoria can match the site in documenting this transition or the underlying engineering ingenuity to achieve the switch from steam power to electric power. The site also is also significant due to its archaeological potential to yield relics associated with turn-of-the century gold mining technology.

[Source: Victorian Heritage Register]

-

-

CASSILIS GOLD MINING COMPANY TREATMENT WORKS - History

Heritage Inventory History of Site: Cassilis Reef was discovered in 1890, the most westerly of seven reefs on a high ridge to the west of the Cassilis townships—it eventually became the main lode of the Cassilis GMC mine. Ore from the Cassilis Reef was heavily mineralised (containing no less than six minerals associated with the gold), and became increasingly so at depth, making gold retrieval virtually impossible using ordinary methods. In 1894, a small syndicate installed a five-head battery and small chlorination plant close to their tunnel. The chlorination plant proved inadequate and was replaced by a larger one in 1896, but still the ore proved too refractory.The Cassilis GMC was formed in 1897, with a capital of £12,000 in 24,000 shares. Extensive exploratory works were carried out—shafts sunk, tunnels driven—and the chlorination plant was further enlarged and improved. Test parcels of the ore (solid arsenical pyrites) yielded 5 oz to the ton. In 1898, the Cassilis Co. purchased the leases of the neighbouring North Cassilis Co. where an incredibly rich reef was soon after opened up—this lode was called the Ceresa. Additional treatment plant was installed in 1899: a Halley table, Berdan pan, a hand-operated reverberatory furnace. The Cassilis Co. had been having its ore crushed at the Warden battery, but in 1900 the company bought a 20-head battery from the Mt Hepburn Co. and installed it at the foot of the range, in Power’s Gully. During 1900-01, further plant was installed at the new site: a Jacques rock-breaker, two Edwards mechanical furnaces, and a new chlorination plant operating on the Munktell process using seven 11-ton leaching vats, seven precipitating vats, and six other accessory vats. A gravity tramline ran between mine and plant. In 1902, a new compressor, additional furnace, new engine, offices, and workshop were added. The large compressor delivered compressed air over two miles uphill to the mine, to power ten rock drills; its engine had a very heavy fly-wheel, to maintain an even speed to ensure constant air pressure at the mine. The company increased the capacity of its dam in Power’s Gully to 3 million gallons, and piped the water race from dam to battery. By 1903, the Cassilis Co.’s sprawling plant also included a dynamo to supply electric light, two large Berdan pans, amalgamating barrel, Kelly and Lewis vertical 150-hp engine, two large Cornish boilers (26 ft x 6 ft 6 in), two multi-tubular boilers (14 ft x 5 ft 6 in), and a cyanide plant of five 80-ton vats. Over 200 men were employed in the mine and treatment plant, with another hundred or so employed indirectly in carting, and supplying wood, charcoal, and lime.Additions to the Cassilis Co. plant continued in 1905, when 130 men were employed and 13,450 tons of ore were treated for a yield of 12,032 oz gold. The gravity tramline between mine and battery was replaced; a Hornsby oil-engine was installed for driving furnaces, conveyors, elevators, machines in shop, dynamo, and blowers (cheaper and more efficient than coke); and a foundry was erected, complete with testing-room and cupola furnace, enabling the company to ‘work up all the old iron and steel obtainable in the district, making a great saving in the manufacturing of numerous parts of the plant’. A telephone system was also installed. The company’s works were described as ‘quite a model plant’.The shortage—and consequent high cost—of firewood threatened to undermine the company’s ‘handsome profit’, so it was decided to construct a hydro-electric scheme, operating from the Victoria River, to power the mine and treatment plant. The scheme was completed in 1907, and by 1909 all old engines at the Cassilis Co.’s works were replaced with electric motors. But the holding dam for the hydro-electric works was never finished, and the company’s operations were crippled by power shortages during the drought years from 1910-14. In 1909, a new electrically-powered rotary air compressor was added to the Cassilis Co.’s plant, which was hailed as ‘one of the most extensive and complete in the State’. A new plant was installed in 1910 for treatment of the accumulated slimes by the vacuum filter process (replacing the chlorination plant), and the following year a tube mill was erected for re-treating residues from the roasting furnaces by the cyanide process. But output from the mine was falling—largely due to power shortages—and the ore from deeper levels was becoming increasingly difficult to treat. A grant from the Mines Department, enabled the company to prospect still deeper, in search of better ore—to no avail. Actual mining was confined to the Ceresa lode, which grew increasingly thin and poor in quality. By 1916, the Cassilis Co. was defeated and its mine and works closed.Between 1898-1916, the Cassilis Co.’s workings—by adit and internal shaft—reached a maximum depth of 1,300 ft, and 124,607 tons of ore were treated for a yield of 93,572 oz, valued at £383,645. The Cassilis Co. mine was the largest and most successful on the Cassilis field.From 1949, ore from the Cassilis mine was treated at Avery’s furnace plant at the Mt Hepburn/King Cassilis mine. Mining exploration of the former Cassilis Co. leases has taken place on several occasions since.Heritage Inventory Description

CASSILIS GOLD MINING COMPANY TREATMENT WORKS - Heritage Inventory Description

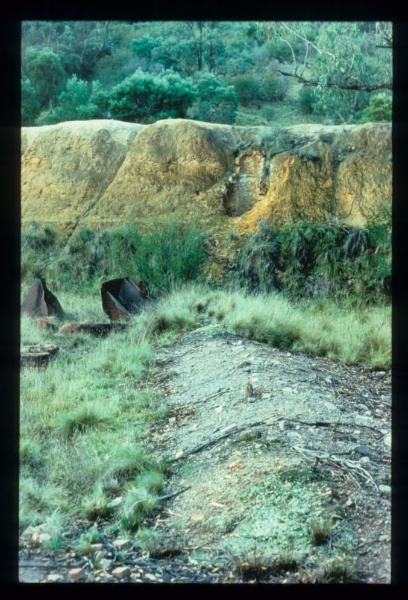

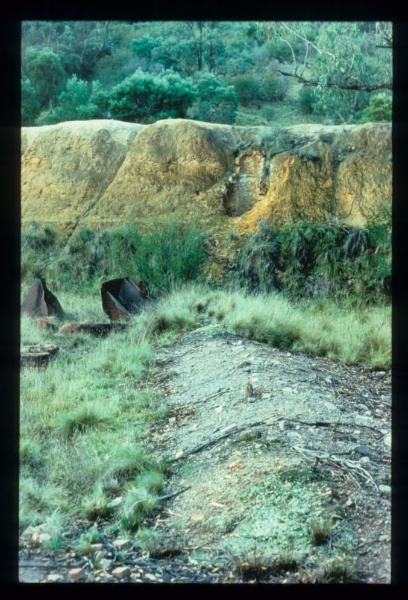

Works have four main levels: Level 1 - large loading ramp remains. Level 2 - battery foundations and engine beds. Level 3 - levelled area, vat outlines, iron furnace. Level 4 - gully level unidentified foundations, roasting furnace remains, electricity substation foundations.

Heritage Inventory Significance: National EstateHistorical significanceùlargest and most successful mine on the Cassilis field; most extensive treatment plant in Victoria in 1900sScientific significanceùrange of features

Heritage Inventory Site Features: CASSILIS GMC TREATMENT WORKSThe treatment works is located on a spur overlooking a gully containing a number of intact (brightly-coloured) slum ponds. The works has four main levels:Level 1 (uppermost)ùThis level has the remains of a large loading ramp which was fed by a tramway that runs around the spur to the mine workings. Level 2ùOn this level are the battery foundations and engine beds. The front of the platform [WHAT PLATFORM?] is retained by a substantial brick wall. BatteryùAt the base of the ramp are a row of decaying mortar blocks, tie bolts and concrete footings for 20 head of stamps. Battery engineùAn arrangement of large concrete mounting beds are located on the side of the loading ramp. Covering 10 m square, they are partly buried and obscured by blackberries. Level 3ùFeatures on this level include:Levelled areaù25 m x 10 m retained by a substantial brick and stone wallVatsùOutlines of a row of five narrow (10 ft x 4 ft) brick and concrete-rendered vatsFurnaceù20ft-high riveted iron furnace. The 6ft-diameter furnace is completely lined with red fire bricks and has a 9 ft high, 3 ft diameter, chimney stack. Level 4ùGully level. Unidentified foundationsùAt the foot of the brick and stone wall associated with Level 3 is a largely buried arrangement of decaying bedlogs and concrete footings. Furnace bedùAt the base [?] of the first slum pond is the remains of a roasting furnace. Most of its brickwork has been demolished; only the stone base is intact, measuring approximately 40 ft x 10 ft. Visible in the face of the first slum pond is a section of the furnaceÆs brick chimney stack, standing 8 ft high. Its flue measures 4 ft wide, with walls [OF FLUE OR STACK?] two courses thick. Electricity substationùOn the opposite side of the gully to the iron furnace on Level 3 are the concrete foundations of a small electricity substation. The foundations are enclosed by thick blackberries.

-

-

-

-

-

CASSILIS GOLD MINING COMPANY TREATMENT WORKS

Victorian Heritage Register H1941

Victorian Heritage Register H1941 -

CASSILIS GOLD MINING COMPANY TREATMENT WORKS

Victorian Heritage Inventory

Victorian Heritage Inventory

-

-