FORD MOTOR COMPANY COMPLEX

365-455 MELBOURNE ROAD NORLANE, GREATER GEELONG CITY

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

What is significant?

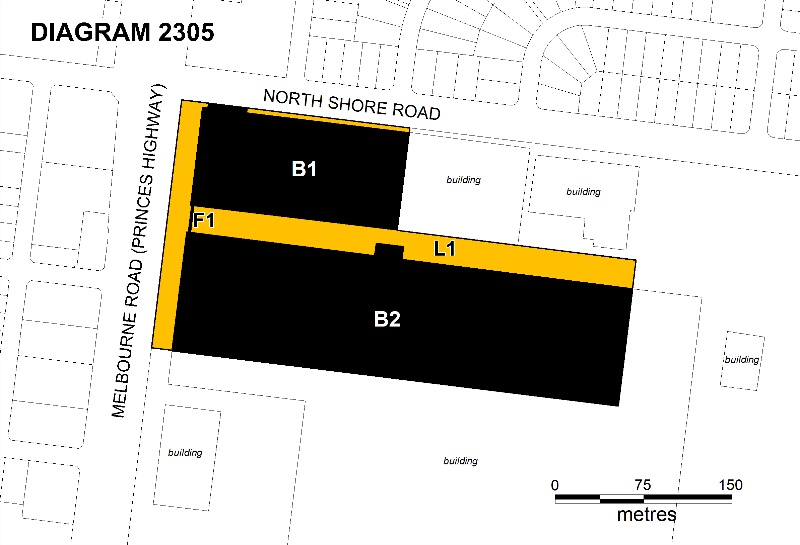

The Ford Motor Company Complex in Norlane, a suburb of Geelong, consists of two steel-framed factory buildings with attached offices behind red brick and painted render Stripped Classical style facades separated by a laneway with brick gate piers marking the entry on Melbourne Road. The buildings were constructed in stages between 1925 and 1942. Six Canary Island Palms (Phoenix canariensis) line the front of the buildings and contribute to the formal presentation of the Place.

After the Commonwealth government banned the importation of car bodies during World War I, Ford fitted imported chassis with bodies made in small plants in several states. In the interests of uniformity and efficiency, the Ford Motor Company of Canada, which ran Ford's operations throughout the British Commonwealth, opted to establish an Australian headquarters in Geelong. A manufacturing plant was to supply bodies to an adjacent assembly plant, as well as to assembly plants in four other states. A 40 hectare site was purchased from the Geelong Harbour Trust in March 1925 and the two buildings were completed in 1926. The engineers were Fyvie and Stewart in association with architect W.J. Grassick. The builder was Concrete Constructions Ltd and the steel was fabricated by Johns and Waygood. From 1908, Ford had developed assembly line methods for mass production, culminating in the Model T in 1913. From 1918, Ford's architect Albert Kahn designed a new type of plant building to suit the assembly line. This widely applied solution was used by Ford Canada for its 1923 Toronto plant, which in turn provided the model for the Geelong buildings. The offices fronting the Geelong assembly building housed the headquarters of the Ford Motor Company of Australia and those fronting the manufacturing building housed the Ford Manufacturing Company of Australia.

The first Model As produced at Geelong were distributed in mid-1928. From 1934 up to 1942, both buildings were extended eastwards in the same configuration. Ford developed military vehicles at Geelong for the Defence Department from 1936, and commenced large-scale production of military vehicles and armaments in 1939. By the company's fiftieth anniversary in 1953, Ford was Geelong's biggest employer with over 5000 workers, and the manufacture of V8 engines was introduced. In 1959, assembly operations were moved to a major new plant at Campbellfield, north of Melbourne, and the Australian headquarters was shifted there in 1961.

The fronts of both buildings feature offices behind Stripped Classical style facades in red brick and render. The long factory side-walls feature a more simplified scheme of curtain-walling with rendered concrete columns and lintels and steel framed windows with brick panels below. The factories have a steel-framed structure providing a broad unimpeded central manufacturing space, flanked by craneway bays. The undersides of the trusses of the manufacturing spaces are designed to support overhead trolleys and services for the assembly lines below. The arrangement of central 'M' roof with flanking smaller 'A' roofs and gabled craneway roofs has continuities with Ford plants of the period world-wide. The various clerestory windows were designed to provide copious day-lighting and ventilation. Roofs were clad in heavy corrugated asbestos cement with concrete slabs for the flat sections.

This site is part of the traditional land of the Wathaurung people.

How is it significant?

The Ford Motor Complex is of historical, technological, social, aesthetic and architectural significance to the State of Victoria.

Why is it significant?

The Ford Motor Company Complex is of historical significance as the site of the headquarters and manufacturing arm of the first major overseas motor vehicle manufacturing company to set up operations in Australia. The Complex is emblematic of the growth of new manufacturing industries from the interwar to the early postwar periods. It is also of historical significance as the first headquarters of one of the major vehicle manufacturers which became household names in Australia.

The Ford Motor Company Complex is of historical and technological significance as the first large factory complex in the State designed specifically to accommodate mass production using assembly line methods.

Ford Motor Company Complex is of architectural significance as a relatively intact example of a large-scale industrial complex of the interwar period which integrates Stripped Classical style facades with a modern steel-structured factory building designed for the assembly line. The Complex is also of architectural significance for its innovative design and the way in which it was influenced by international developments in the planning and architecture of large-scale manufacturing plants during the interwar period.

The Ford Motor Company Complex is of aesthetic significance as competent example of the interwar Stripped Classical style of building that, in scale and overall composition, presents powerfully to Melbourne Road.

The Ford Motor Company Complex is of social significance to the community of Geelong for the central role Ford has played in the development of Victoria's second major city over some 50 years.

-

-

FORD MOTOR COMPANY COMPLEX - History

Contextual HistoryThe assembly line for Model T Fords that would revolutionize the industry began operating at Ford's Highland Park factory by 1913, and this greatly reduced the costs of the cars. The company had started exploring assembly line methods as early as1908. There were industrial processes operating well before this time which encompassed some of the features of what we now consider to be the assembly line. In the late nineteenth century meatworks used overhead trolley systems to move carcases past stationery workers, each of whom repeated the same cutting operation, in what were effectively dis-assembly lines. The Ford Motor Company was said to have taken cues from Chicago examples of these dis-assembly lines. Other motor vehicle manufacturers including the Olds Motor Vehicle Company had also been exploring this technology, although Ford was the first to apply conveyor belt systems to the process. Soon Ford factories in Europe were applying the new technology, and other motor vehicle manufacturers either followed suit of failed.

Beginning with the River Rouge plant in 1918 Ford's new plants were redesigned to suit these new technologies. Extendable single storey buildings with unimpeded spaces allowed free and efficient arrangement of machinery and flow of materials. This internal layout, and the steel structure and facade treatment which Ford's architect Albert Kahn applied, was soon applied to the many assembly buildings which followed in the USA and Canada in the 1920s. ('Ford Richmond Assembly Plant - Architect Albert Kahn' on Ford Motor Car Company History website, http://fordmotorhistory.com/factories/richmond/albert_kahn.php, accessed 18 April 2012)

References to 'assembly lines' first appear in Australian newspaper reports around 1919, usually in articles about American industries employing that system of production. See for instance a description of a Buick transmission "assembly line" in the USA that appeared in an Adelaide paper in 1919. (The Mail [Adelaide], 18 October 1919 p.18.) The nineteenth century dis-assembly lines that had inspired the new technology were also present in Australia at such sites as the Morts and Co. meat preserving works in Sydney. In Victoria, one of the earliest mentions of application to machinery manufacture involves Ralph McKay, nephew of H.V. McKay and factory superintendent at the Sunshine Harvester Works, who visited the USA and Europe in 1921 to study modern assembly-line technology and labour-management practices. This is said to have influenced modernization of the Sunshine factory and the introduction of female workers to their production line in 1922. (Kerville, D., 'McKay, Ralph (1885-1959)', Australian Dictionary of Biography, National Centre of Biography, Australian National University, http://adb.anu.edu.au/biography/mckay-ralph-10979/text19517, accessed 18 April 2012) These moves, however, do not appear to have been reflected in the establishment of modern assembly line techniques in Victoria prior to the Ford Geelong plant. A visiting Ford executive remarked of the Sunshine Harvester Works that "the firm had adopted and enormous amount of labour saving machinery, but their shop lay-out is such as to indicate that that they have little conception of getting the lowest possible cost of production". Australian factory buildings too were still little different from 19th century types. (Easdown1987 pp.27-9)

Ford opened its first Australian branch in 1909, importing fully assembled cars. During World War I the Australian government banned the importation of car bodies to save shipping space. After the war heavy tariffs were imposed on imported motor vehicle bodies. With these encouragements, by the early 1920s the Australian motor vehicle manufacturing consisted of a number of small body manufacturers who imported their chassis and engines from large overseas companies such as General Motors and Ford. All five Ford distributors manufactured their own bodies. Prices for vehicles were very high. Under these conditions, most of these manufacturers continued to use relatively primitive manufacturing methods, but in the early 1920s Holden's Motor Body Builders in South Australia had modernized its manufacturing methods for building bodies for Dodge and General Motors, undercutting the prices of Fords. (Wilkins 1964 pp.124-5)

Ford Canada was chosen to organize a competitive manufacturing capacity in Australia. As a British Commonwealth member, Canadian imports enjoyed reduced tariffs because of Canada's favoured nation status, and Ford Canada was already producing right-hand-drive cars for the British market. In the interests of uniformity, efficiency and reduced cost, Ford Canada opted to introduce a headquarters and centralized body manufacturing plant in Victoria, with an accompanying assembly plant as well as assembly plants in the other states. Ford Canada executives toured Australia from 1923 and chose the Geelong site in March 1925. General Motors would not make a similar move until 1931 when it took over the ailing Holden's Motor Body Builders in Adelaide. (Tuckey 2000 p.1)

Place HistoryIn March 1925 Ford selected a 100 acre (forty-hectare) site at North Geelong from a number of potential sites in Victoria. This site was promising for distribution, enjoying proximity to deep-water harbour facilities and ready availability of a railhead for inland transport. It also promised ready energy supplies and steady labour conditions. (Wilkins 1964 pp.125-6) It was purchased form the Geelong Harbour Trust, which was to supply the quay and dredge the required channels. (Argus, 30 March 1925 p.11)

The recently completed Ford Ontario works was to be the model for the Geelong building, which also was to be of one storey and capable of expansion. A press release in March 1925 stated that existing building designs would be reviewed and "definite building plans" would be placed before the consulting engineers Fyffe and Stewart. In "appearance and convenience of layout" the Geelong plan would compare favourably with recent plants in Canada. Only high-class materials would be used, with preference given to Australian products. (Argus, 31 March 1925 pp.19-20; 1 April 1925 p.21)

Fyffe and Stewart worked in association with architect/engineer W.J. Grassick. Grassick started his career as an engineer in Ireland and moved to Victoria in 1911. His practice became increasingly architectural, and in 1922 he made the first in a series of unsuccessfully applications for registration as an architect. From that year, however, his association with Fyffe and Stewart would lead to an increasing specialization in factory design. (Reeves 2009 p.25) The precise extent of his contribution at Ford Geelong is unknown, but the close similarities of the design to North American precedents indicate that he had a limited role. He did, however, make use of what he had learnt at Geelong in his subsequent factory designs, including buildings for the Larkin Aircraft Company at Coode Island. "Mr Grassick . incorporated in the hangars and workshops the Ford idea of building clear of all internal supports, so that the various machines can be moved about the enclosed space at any moment and assembled where the greatest pressure of work exists at any moment." (Argus, 26 April 1927 p.8) Grassick went on to design a number of factories in the Moderne style up until the late 1950s.

No documentary evidence has been found of the of the common and still current story that the structural design of the Geelong roofs was predicated on North American snow loads, and that the Australian proponents had had to inform the Ford Canada representatives that this was an unnecessary expense in Australian conditions. It seems very unlikely that North American designers were unaware of such matters given that Ford factories were being constructed in the warmer southern reaches of that continent as well as in the snowy north. The same story has been applied to the much later Ford headquarters building at Campbellfield.

The Concrete Construction Company was engaged to build all of the Ford works in Australia. Johns & Waygood Ltd of South Melbourne won the contract to supply and fabricate the 1500 tons of structural steel for the two Geelong buildings. (Advocate [Burnie], 28 May 1925 p.5. Argus, 16 June 1925 p.9) The window operating system was designed and manufactured in Australia, with the same system installed later at the South Australian Ford assembly plant, at which point it was described in detail. "Huge steel frames, measuring 25ft by 5ft are set in the wall at heights varying from 50 to 85 ft from the ground. Thee are all controlled by an electrically driven motor, and by pressing a button they can be opened and shut." This enabled clearing of smoke and gas from any part of the factory, and the catching of "cool air currents". Inside temperature during hot weather at the South Australian plant was found to be 15°F less than shade outside. It was a principle of management that lighting should be "as near as possible to daylight". This necessitated frequent window cleaning, with a special steel tower travelling on rails, made in Australia and "considered to be the best window device in any Ford plant in the world". (Advertiser [Adelaide], 14 April 1926 p.13)

The offices fronting the southern manufacturing building were to accommodate the headquarters of the Ford Manufacturing Company of Australia. The offices fronting the northern assembly building, which was started first, were to accommodate the national headquarters of the Ford Motor Company of Australia. The buildings were completed in 1926. The first assembly line was reputedly a crude and shortened version of those in the USA and Canada, at only twelve metres long. (Ford Australia, 1983 p.3)

There was to be no piecework at the new factory, as this was contrary to Ford policy. Fifteen workmen and their families were brought from Canada "to lay the foundation for the factory policy". Ford Canada was worried that Australian workers would not know how to operate in the new conditions. (Mail [Adelaide], 4 December 1926 p.27. Argus, 25 April 1925 p.21) Fears about the impact on health of the repetitive work created by the assembly line, which were becoming common around the industrialized world, also surfaced in Australia. In 1938 it was observed that no workers over the age of forty remained in the Geelong factory, the older men all having been "worn out and put on the scrap heap". (Townsville Daily Bulletin, 11 May 1938 p.6)

The first Model As were produced at Geelong in July 1928, and over 32,000 were built in Australia by 1932. (Argus, 12 May 1928 p.19. Advertiser [Adelaide], 13 July 1928, p.18. Ford Australia 1983 p.23. Easdown 1987 pp.36-7) From 1934 up to 1942 as the company expanded the assembly and manufacturing buildings were extended eastwards in the same materials, finishes and configuration. A c1945 schematic drawing of the site shows the order and scale of the additions. It also shows the frontage to the highway with simple lawns and a row of low (i.e. young) palms in similar position to those currently in place. (Authentic Heritage Services 2000 Citation for Ford Motor Company Complex p.6) In 1934 a 33,000 sq. ft. addition was made to the body works, as well a large drying kiln constructed for the seasoning of the timber used in bodywork. (West Australian, 31 May 1934 p.7) (This may be the extant small building in the central open area between the assembly and manufacturing buildings.) In 1935 another extension was announced. (Gippsland Times, 8 August 1935 p.2) In the same year a new assembly plant at Lidcombe Sydney was completed. (Argus, 3 December 1935 p.5) In 1937 the biggest extension to the manufacturing plant yet was announced, in response to strong sales as well as to the Commonwealth Government allowing an undisturbed quota for the following two years. £150,000 was to be spent on building and machinery, including the larger presses required to produce the new one-piece roof. The new building was to be constructed by J.C. Taylor and Sons, Geelong. (Argus, 4 September 1937 p.17. Canberra Times, 4 September 1937 p.8) In 1941 Ford completed a £100,000 extension to allow completion of its quota of cars and for armament construction. (Advocate [Burnie], 6 October 1941 p.2)

Prior to the start of the war, Ford had, in cooperation with the Department of Defence, been designing and manufacturing a variety of vehicles based on its V8 forward control truck chassis for haulage of artillery and transport of associated personnel and equipment. (Argus, 20 October 1936 p.5) In 1939 Ford and the Commonwealth Supply and Development Department planned a new Annex on adjacent land for munitions production, and manufacture of mine bodies commenced there in 1940. All tooling for pressing of the metal cases of the mines was undertaken by Ford engineers. (Canberra Times, 23 September 1939; 12 September 1940; 29 November 1940 p.6) Ford also commenced large-scale production of military vehicles and a wide range of other equipment. Nearly 100 different body types of military vehicle were produced. Over 65,000 auxiliary fuel tanks for planes were made at the plant. (Easdown 1987 pp.53-4) Numerous women munitions workers were employed in a wide variety of tasks at the Geelong plant during the war. (See a series of shots of women munitions workers taken by the Herald newspaper, Australian War Memorial photos Nos. 138959, 138775, 138776, 138956, 138957, 138772.)

During World War II it had become apparent that Australia's manufacturing capacity would have been most inadequate in the event of an invasion. As a result, after the war the government was determined to increase industrial capacity, and the current pattern of importing motor vehicle chassis from overseas was an immediate target. Manufacturers were invited to put forward proposals for complete manufacture of vehicles. The General Motors Holden (GMH) proposal was the first to be adopted. Ford's initial proposal, which called for government subsidies and assistance, was rejected, but a subsequent proposal of more modest dimensions was accepted. These agreements set the scene for new investment in buildings and equipment. (Wilkins 1964 pp.351-2) In 1950 Ford made plans for the Geelong plant to start to manufacture transmissions, engines and axle assemblies, with the eventual goal of 93% Australian manufacture. By July 1950 50% of Fords V8, 48% of its truck, and 56% of the Ford Prefect were built in Australia. (Wilkins 1964 p.400)

The large motor vehicle assembly and manufacturing plants, including Ford Geelong and the GMH plant at Fishermens Bend, became emblems of the type of advanced industrialization required for Australia in the post-war world. Graeme Davison writes that "The car factories were not only powerhouses of economic growth; they were also a paradigm of flow technology, streamlined efficiency and synchronised activity that soon set the standard for the whole of modern life". (Davison 2004 p.85) This comparison was applied with special frequency to the housing industry. For instance, a 1956 Argus report on the Phelan prefabricated house was headlined ".houses can be built on the assembly line principle". (Argus, 26 July 1956 p.15) The high volume of tours of the plant, which started early and became almost a standard part of the education of Victorian children, not to mention adult groups of all persuasions, helped to secure the longstanding place of Ford Geelong in the public imagination. (Argus, 7 April 1926 p.6) Politicians too made frequent visits to the plants of the major car manufacturers. In 1946 Prime Minister Chifley visited the Norlane plant on the occasion of the twenty-first anniversary of the Company's start in Geelong. (Argus, 2 July 1946 p.21)

The Commonwealth government used Ford Geelong as an example of employment opportunity in post-war promotions geared at attracting new migrants. By1954 54% of workers at the Geelong factory were immigrants. (See for instance a series of 1956 Commonwealth government promotional images held by the National Archives, including Image Nos. A12111, 1/1956/16/1,2,3 & 4 and 1/1955/16/12A3, in which the Ford plant is the clearly visible setting.) We also know that a large proportion of the residents of the adjacent Norlane housing estate, many of whom worked at Ford, were migrants. (Eather 1988 p.91)

By the company's fiftieth anniversary in 1953, Ford was Geelong's biggest employer with over 5000 workers. The previous year the manufacture of V8 engines had been introduced, with a modern overhead engine assembly line. "Automatic machines do the whole job of assembling the engines, even to filling them with oil ." (Argus, 2 March 1953 p.21. Ford Australia 1983 p.23)

From its first years the Ford factory to the north of Geelong was a major stimulus to new housing in the area. In the initial stages Ford had planned to provide workers dwellings near to the plant, but by the time construction started the Company's position was that this should be handled by the existing State housing scheme. (Argus, 1 April 1925 p.1) In April 1926 a private subdivision named 'Fordtown' was opened for inspection. The 117 lots were advertised as being only 100 feet from the Ford plant. (Argus, 31 March 1926 p.26; 7 April 1926 p.6) From 1943 the Housing Commission of Victoria (HCV) had a policy of facilitating decentralization of industry, and up to 1948 a few small estates were allocated to newly established industries in country towns, but successive governments pushed a policy of allocation based purely on need. (Eather 1988 p.73) There was rapid increase in industrial activity in Geelong in the post-war period, including expansions at major existing employers in North Geelong such as Ford, Pilkington Glass and the Australian Cement Company, as well as a number of new industries in the same area. This coincided with a severe shortage of worker accommodation. The HCV's decision to commence an estate at Norlane was made in 1946 and building commenced in 1948. Building continued over a ten-year period, by which time Norlane was the largest of the Housing Commission's country estates. (Eather 1988 pp.86-88) Ford approached the Commission for allocation of houses at Norlane but was rebuffed. (Eather 1988 p.91) While houses at Norlane were not allocated specifically to Ford employees, Warwick Eather's survey established that in the early estate around 50% of residents were employed at either Ford, the Shell Refinery or the International Harvester Company. (Eather 1988 p.73)

The Geelong factory was expanded and modernized again in 1958 and assembly operations were moved to a major new plant at Campbellfield, north of Melbourne, in 1959. The original Assembly plant at Geelong was now made over for manufacture of engines and transmissions. Ford Australia's headquarters was shifted to Campbellfield in 1961. The era of the primacy of Ford's Geelong plant was now over, but the importance of the plant to the local economy remained. In 1983 Ford was still employing twelve per cent of Geelong's workforce. (Ford Australia 1983 p.9)

BibliographyAuthentic Heritage Services (2000). Greater Geelong Outer Areas Heritage Study: Stage 2. Geelong, City of Greater Geelong.

Davison, G. (2004). Car Wars: how the car won our hearts and conquered our cities. Sydney, Allen & Unwin.

Easdown, G. (1987). Ford, a History of the Ford Motor Company in Australia. Sydney, Golden Pres.

Eather, W. (1988). We Only Build Houses: the Commission 1945-60. New Houses for Old: Fifty years of Public Housing in Victoria 1938-1988. R. Howe. Melbourne, Ministry of Housing and Construction.

Ford Australia (1983). Ford in Australia: 1925-1983. Campbellfield, Victoria, Ford Australia.

Reeves, S. (2009). "Grassick: An Unqualified Success." Spirit of Progress 10(3).

Tuckey, B. (2000). True Blue: 75 Years of Ford in Australia. Sydney, Focus Publishing.

Wilkins, M. and F. E. Hill (1964). American Business Abroad: Ford on Six Continents. Detroit, Wayne State University Press.

FORD MOTOR COMPANY COMPLEX - Plaque Citation

Opened in 1925, this was the first new manufacturing plant set up by a major international motor-vehicle manufacturer in Victoria, and also the first factory purpose-built to accommodate a moving assembly line.

FORD MOTOR COMPANY COMPLEX - Assessment Against Criteria

ASSESSMENT AGAINST CRITERIA

a. Importance to the course, or pattern, of Victoria's cultural history

The Ford Motor Company complex Geelong is of historical significance as the site of the headquarters and manufacturing arm of the first major overseas motor vehicle manufacturing company to set up operations in Australia. The Ford Factory Geelong was emblematic of the successful industrialization of Victoria and Australia in the inter-war and early post-war periods. The Ford Factory Geelong also used as an exemplar of the success of Fordism in a period when this approach was widely advocated for application in other industries including housing.

The Ford Motor Company complex Geelong is of historical significance for its capacity to represent the harnessing of Australian industrial capacity for production of war material. The Ford Factory Geelong also featured as an important exemplar in wartime propaganda for the role of Victorian and Australian industry.

The Ford Motor Company complex Geelong is of historical significance as a major employer of post-war migrants. The factory was also used as an exemplar of the employment possibilities for migrants in Australia.

The Ford Motor Company complex Geelong is of historical significance for its connection to an early conjunction between industry and the Victorian Housing Commission's housing programmes. The development of the Commission's large Norlane estate from 1947 was closely tied to the presence of the Ford Motor Company in the area, along with other large industrial employers.

b. Possession of uncommon, rare or endangered aspects of Victoria's cultural history.

c. Potential to yield information that will contribute to an understanding of Victoria's cultural history.

d. Importance in demonstrating the principal characteristics of a class of cultural places or environments

The Ford Motor Company complex demonstrates the principal characteristics of a large-scale industrial complex of the interwar period.

e. Importance in exhibiting particular aesthetic characteristics.

The Ford Motor Company complex Geelong is of aesthetic (architectural) significance as a relatively intact example of a large-scale industrial complex of the interwar period which integrates Stripped Classical style facades with a modern steel-structured factory building designed for the assembly line. In its close continuities with a number of Ford assembly plants in the USA and Canada the design is also expressive of the global enterprise of Ford.

f. Importance in demonstrating a high degree of creative or technical achievement at a particular period.

The Ford Motor Company complex Geelong is of scientific/technological significance as the first large factory complex in the State designed specifically to accommodate mass production using assembly line methods.

g. Strong or special association with a particular community or cultural group for social, cultural or spiritual reasons. This includes the significance of a place to Indigenous peoples as part of their continuing and developing cultural traditions.

The Ford Motor Company complex Geelong is of social significance as a major long-term employer in the second major city of the State. The complex is also of social significance as the first headquarters of one of the major vehicle manufacturers which became household names in Australia.

h. Special association with the life or works of a person, or group of persons, of importance in Victoria'sFORD MOTOR COMPANY COMPLEX - Permit Exemptions

General Exemptions:General exemptions apply to all places and objects included in the Victorian Heritage Register (VHR). General exemptions have been designed to allow everyday activities, maintenance and changes to your property, which don’t harm its cultural heritage significance, to proceed without the need to obtain approvals under the Heritage Act 2017.Places of worship: In some circumstances, you can alter a place of worship to accommodate religious practices without a permit, but you must notify the Executive Director of Heritage Victoria before you start the works or activities at least 20 business days before the works or activities are to commence.Subdivision/consolidation: Permit exemptions exist for some subdivisions and consolidations. If the subdivision or consolidation is in accordance with a planning permit granted under Part 4 of the Planning and Environment Act 1987 and the application for the planning permit was referred to the Executive Director of Heritage Victoria as a determining referral authority, a permit is not required.Specific exemptions may also apply to your registered place or object. If applicable, these are listed below. Specific exemptions are tailored to the conservation and management needs of an individual registered place or object and set out works and activities that are exempt from the requirements of a permit. Specific exemptions prevail if they conflict with general exemptions. Find out more about heritage permit exemptions here.Specific Exemptions:General Conditions: 1. All exempted alterations are to be planned and carried out in a manner which prevents damage to the fabric of the registered place or object. General Conditions: 2. Should it become apparent during further inspection or the carrying out of works that original or previously hidden or inaccessible details of the place or object are revealed which relate to the significance of the place or object, then the exemption covering such works shall cease and Heritage Victoria shall be notified as soon as possible. General Conditions: 3. If there is a conservation policy and plan endorsed by the Executive Director, all works shall be in accordance with it. Note: The existence of a Conservation Management Plan or a Heritage Action Plan provides guidance for the management of the heritage values associated with the site. It may not be necessary to obtain a heritage permit for certain works specified in the management plan. General Conditions: 4. Nothing in this determination prevents the Executive Director from amending or rescinding all or any of the permit exemptions. General Conditions: 5. Nothing in this determination exempts owners or their agents from the responsibility to seek relevant planning or building permits from the responsible authorities where applicable. Asbestos: Asbestos removal and replacement of the remaining areas of asbestos cement roofing with fibre cement sheeting.. Minor Works : Note: Any Minor Works that in the opinion of the Executive Director will not adversely affect the heritage significance of the place may be exempt from the permit requirements of the Heritage Act. A person proposing to undertake minor works must submit a proposal to the Executive Director. If the Executive Director is satisfied that the proposed works will not adversely affect the heritage values of the site, the applicant may be exempted from the requirement to obtain a heritage permit. If an applicant is uncertain whether a heritage permit is required, it is recommended that the permits co-ordinator be contacted.The following works relating to the exteriors and interiors of the buildings are also exempt:

1. Removal of crank-operated NACO vertical window louvers, and associated equipment

2. Replacement of glazing panels to original multi-paned window bays (replacement panels must be readily removable to allow glazing to be reinstated)

3. Replacement of Fibrolite cladding to roofs and gable end walls with flat FC sheet

4. Replacement of roof cladding (predominantly asbestos cement) with metal sheet cladding.

5. Replacement of all roof-mounted plant and equipment and introduction of new as required on the condition that all such work is concealed in all views from Melbourne Road.

6. Demolition of non-original first floor offices at the west end of B1 (c.1940s). The removal of the small monitor roof forms is not exempt.

7. Demolition of non-original single-storey brick additions (women's cloakrooms) date unknown, possibly 1940s on northern side of B1 at its western end.

8. Repair and maintenance of hard and soft landscaping. The removal of the palm trees on the Melbourne Road frontage is not exempt.

9. All internal works, other than where these impact on the external appearance of the building or on surviving decorative dado

10. Replacement of concrete floor slabs (continually replaced over the life of the factory)

11. All sub-floor works including construction of new pits as required

12. Removal, relocation or reconfiguration of plant and equipment, access ladders, walkways and the like. With the exception that the surviving remnants of the window operating systems be retained.

13. Removal and replacement of all lighting, signage and services

14. Demolition/removal of non-original structures that have been erected on the factory floor and introduction of new structures as required

15. Internal alterations/refurbishment of all wet areas, including to the original elevated toilet block, excluding works to the perimeter walls or ceilings of the wet areas.

16. Painting of previously painted internal surfaces including original pencil-pointed brick walls

17. Demolition of the two-storey 1970s/80s office blocks in the south wing, and apprentice training room.

18. Removal of existing internal fitout and all internal refurbishment works to the two storey brick locker room internal to the western end of B2 (internal fabric is c.1950s).

19. Removal of existing internal fitout and all internal refurbishment works to the former boiler house (gable-roofed building on the north side of B2)

FORD MOTOR COMPANY COMPLEX - Permit Exemption Policy

The purpose of the Permit Policy is to assist when considering or making decisions regarding works to the place. It is recommended that any proposed works be discussed with an officer of Heritage Victoria prior to making a permit application. Discussing any proposed works will assist in answering any questions the owner may have and aid any decisions regarding works to the place. It is recommended that a Conservation Management Plan is undertaken to assist with the future management of the cultural significance of the place.

While this is an active industrial site with constant change to factory processes, services and machinery, there is an expectation that changes will be made to allow the current use and continuing uses of the building. These buildings were originally designed to allow easy changes to production lines and processes, and there have been many changes on the factory floor over the years, such that little early fabric remains in this area. .

Some of the major original components and finishes, such as glazing and rendering, are deteriorating and in need of repair. As noted in the General Conditions, a permit is not usually required for minor repairs to significant fabric in which like is replaced with like. However, this does not apply where such materials are removed and not replaced, or where they are replaced with different material. The maintenance approach for the site should be adjusted to include consideration of the need to retain, conserve and repair such historic fabric.

Where there are some remnants of equipment and services from the earlier periods of operation, particularly attached to the overhead truss system, which might provide information about earlier use and aid in interpretation, this should be retained where possible.

There is potential to reverse some previous changes to the historic fabric, especially on the front facades when the repair materials have reached the end of their useful life.

-

-

-

-

-

FLETCHERS / GEELONG FREEZING WORKS PIER

Victorian Heritage Inventory

Victorian Heritage Inventory -

FORDS WHARF / CORIO QUAY NORTH

Victorian Heritage Inventory

Victorian Heritage Inventory -

CORIO FREEZING WORKS AND ABATTOIR WHARF

Victorian Heritage Inventory

Victorian Heritage Inventory

-

'YARROLA'

Boroondara City

Boroondara City -

1 Bradford Avenue

Boroondara City

Boroondara City

-

-