FORMER FUSE FACTORY

193-197 WATTLE STREET AND 29 VALENTINE STREET IRONBARK, GREATER BENDIGO CITY

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

The Former Fuse Factory appears to have been established sometime prior to 1878 by Charles Perry and John Hunter. Until that time the company had been manufacturers of gratings for crushing machinery at a factory in Forest St. A fire in 1878 appears to have destroyed this business causing a move of all their activities to Wattle St shortly there-after. Although a factory had been established at Wattle St prior to 1878, Perry and Hunter are not shown as owners until after the fire at Forest St. Perry and Hunter then concentrated their activities into exclusively fuse manufacture. Extensions were made to the Wattle St factory in 1883-85 although it is uncertain of what these consisted.

The Cornish fusemakers, Bickford, Smith and Company bought the business in 1889 and enlarged the factory. Further extensions were also made circa 1900. Bickford Smith ceased operations at the site in 1912 and the site was then used by a succession of textile manufacturers. This activity ceased in 1977 and the Ascension Life Centre became owners.

The Former Fuse Factory is of historical and architectural importance to the State of Victoria.

The Former Fuse Factory is of historical importance as the site of the major 19th century manufacturer of safety fuses for the mining industry. The site was first occupied by Perry and Hunter from 1878-79 and it was here that they exclusively manufactured their patent safety fuse for the goldmining industry. The business was bought by Bickford Smith & Co in 1889 and they continued fuse manufacturing here until 1912. During this period the factory was enlarged on at least two occasions. Safety fuses played an important role in the mining industry by reducing death and injury through uncontrolled ignition of explosives.

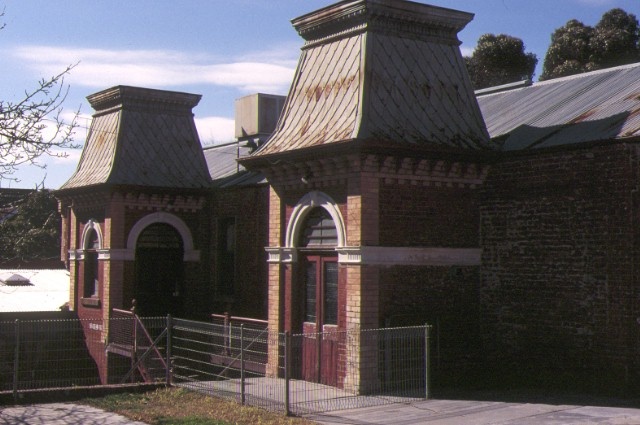

The Former Fuse Factory is of architectural significance as an unusual and prominently located factory building erected and extended over a period of some 30 years. The unusual incorporation of the twin towers and their elaborated mansard roofs over what were once courtyard entries, architecturally distinguish the external appearance of this small scale industrial complex.

-

-

FORMER FUSE FACTORY - History

Contextual History:History of Place:

The location the former Fuse Factory is on the Parish of Sandhurst Plan as allotment 6, section 52. According to the Plan, the Crown alienated the site on 27th December, 1877, and sold it to Peter Rohs, a bonecrusher. The City of Sandhurst valued the land in 1877 and determined the annual rate for the property at £6.00. Late in 1877 or early 1878 Charles Perry and John Hunter bought the site and built a factory on the land. In 1878 the land and factory appeared on the rate book and the assessor valued the whole at £40.00 per annum.

According to W.B. Kimberly, Charles Perry was born in Cornwall in 1832 and emigrated to Australia in 1857. Perry arrived in Sandhurst in November 1857 and began mining for gold before opening a stamper gratings business in 1860. The City of Sandhurst Rate Books indicate that in 1864 and 1865 Perry and William Brooks, manufacturers of grating punchers, rented from the Crown a workshop, house and land in Wattle St. Kimberly suggests that in 1865 Perry formed a partnership with John Hunter. In 1870 John Hunter married Perry’s sister, Mary Catherine Perry. At about this time Perry, an “engineer”, moved to Forest St, initially renting a house and land from William Reynolds before buying his own property in the street.

The Sandhurst Rate Books indicate that John Hunter shifted from renting a house in Williamson St to owning a house and land in Forest St in 1872, when he became known as an engineer rather than a miner or “splitter”. On 17 and 22 March, 1873, Perry and Hunter applied to the Patent Office for joint patents on two inventions for “Pulverizing quartz tailings, pyrites, mineral ores, and gritty substances” and “An improved machine-made stamper grating”. The Perry and Hunter patent applications of 1873 indicate that by at least this year the two men were working in a partnership.

In 1874 John Hunter added a factory to his home in Forest St. The next year Perry and Hunter exhibited at the Philadelphia Centennial Exhibition in Melbourne several varieties of safety fuse and various types of stamper gratings. The exhibit won a second prize and the catalogue cited the products as those of Perry, Hunter & Co. of Forest St, Sandhurst. Hunter’s factory disappears from the Rate Book in 1879 suggesting the destruction of the factory in the year before. In Graeme Butler’s Eaglehawk and Bendigo Heritage Study he states of the Wattle St Fuse Factory that “A fire destroyed the factory in 1878, which was presumably immediately rebuilt”. More probable is that fire destroyed Hunter’s Forest St factory prompting the transferral Perry and Hunter’s manufacturing operation to the newer site in Wattle St. Prior to 1878 the two men possibly ran two separate factories, one in Forest St and the other in Wattle St. Bailliere’s Official Post Office Professional, Commercial, Trade, Farming, and Squatting Directory of Victoria continued to list Perry and Hunter as fuse manufacturers from Forest St in Sandhurst until 1880, although clearly they had shifted their business to Wattle St by 1878.

There is, however, some confusion concerning the date that Perry and Hunter opened their new factory. Although the Parish Plan, Rate and Assessment Books indicate that Perry and Hunter did not pay rates or own the Wattle St property until, at the earliest, 1877, other evidence indicates that they were running a new factory in 1876. Perry and Hunter advertised their business in the Bendigo Advertiser on 15 May, 1876, as the “Bendigo Fuse Factory, Wattle Lane, Sandhurst”. An article in the supplement to the Bendigo Advertiser of 1 May, 1876, referred to Perry and Hunter’s new fuse factory in “Wattle Lane, nearly opposite Mr Ruddock’s Foundry”. The reference to the factory in Wattle “Lane” rather than “Street” appears to be a confusion of street names as other evidence demonstrates that Ruddock’s Foundry was in Wattle St. The dates, however, are irreconcilable.

Prior to 1877, Perry and Hunter were manufacturing stamper gratings and fuses from the factory in Forest St. Perry invented the safety fuse the company produced, and in particular the machine to make the fuse, several years earlier although there is no record that Perry ever patented his fuse design. The Annals of Bendigo state that Perry “did not begin the manufacture of [the] fuse for business purposes until 1873”. Kimberly wrote that Perry and Hunter continued their stamper grating business until 1876. The move to a new factory in Wattle St appears to have involved the cessation of Perry and Hunter’s stamper gratings manufacture and the production solely of the safety fuse invented by Perry.

In 1876 a local publication described the making of Perry’s safety fuse and explained why Perry’s design was safer than other fuses imported from England. The paper described ten spinning bobbins that created an outer webbing of jute and formed the core of the fuse. This core was filled with gunpowder and three gunpowder coated threads “which is claimed by the firm as the distinguishing feature from other manufacturers and accordingly these ‘three threads constitute the firm’s trade mark”. The three internal coated threads increased the reliability of the fuse by ensuring its continuous burning. Finally, an outer layer of yarn coiled in the opposite direction to the first covered the fuse and the whole coated in varnish at 300° F prior to a dip in a whitening agent to reduce sticking.

The paper praised Perry and Hunter for manufacturing a fuse locally and thereby saving many lives and limbs. The main feature of the safety fuse was its water resistance, a vital aspect of its effectiveness considering the primary use of the fuse was in the wet and dank conditions of the underground mine. The firm produced 250 coils of 100ft in length every eight hours. Perry and Hunter’s fuse factory was the only one in Sandhurst and during the 1870’s one of only two or three in the whole of Victoria. Perry and Hunter made extensions to the Wattle St Factory in 1883 and 1887 before selling to whole in 1889 to the Cornish fuse making firm Bickford, Smith and Co. who based their operations in Bristol.

When this English firm, considered by many to be the leading fuse manufacturer in the world, took over Perry and Hunter’s business they did so in the belief that Perry’s safety fuse was one of the best fuses ever invented. The firm built major extensions onto the factory during this period and in 1889/90 rates on the factory totalled £90 and one person, the fuse maker Edward Ernest Burgess, was living on the site. By 1901 the company was paying £150 in annual rates and had bought two residences on either side of the factory. The block on the corner of what is now Valentine and Wattle Streets became a home for the company foreman, William H. Tonkin, which he shared with seven other people.

Eventually the fuse factory closed down, in approximately 1912, as the mining industry dwindled. Bickford, Smith and Co. sold the factory site to the Economic Manufacturing Company, a clothing manufacturer. In 1920 the Annals of Bendigo record that on a royal visit the Mayoress of Bendigo presented Edward, Prince of Wales, with a “gift of sleeping garments” made for him by the women who worked in the factory. After the EMC, Crestknit Australia Pty Ltd bought the factory although the company halted operation in January 1977 and attempted to sell the property the same year. During the 1970’s the site was also a discount store before being bought by the Ascension Life Centre; although the Centre is currently trying to sell the factory to raise funds to build a new Apostolic Church in Kennington.

The original ornamental roof ventilators of the factory and mansard roof towers, similar structural features to other Bendigo buildings, have led the National Trust to speculate that W.C. Vahland designed some parts of the building although no direct evidence exists of the original architect. The City of Greater Bendigo Planning Scheme lists the fuse factory and gives it a “C” classification, although Graeme Butler gave the site an “A” classification in his Heritage Study. The Register of the National Estate listed the factory in 1978 and the National Trust similarly classified the site in 1976. The National Trust describe the factory as “an outstanding nineteenth century factory complex”.

History of Place:

The site is on the brow of the Wattle St hill close by the garden Gully quartz mining area. In 1875 Messers Charles Perry and his nephew John Hunter established a safety fuse manufacturing business. Perry and Hunter were already associated with manufacturing crushing plant gratings for the mining industry.

the industry had been using fuses of inferior quality at that time and the Bendigo Advertiser of 1876 commended the company’s efforts in perfecting a workable fuse for mining activities .

The plant consisted of steam engine and vertical tube boiler which drives overhead line shafting. The equipment employed bobbins to weave 3 strands of hemp into a fuse with a black powder and cotton core. Heated vats were employed to keep varnish in a molten state. The Varnish was then applied to the hemp to make the fuse waterproof.

The business was sold in 1888 to Bickford Smith of Bristol and extensions were made to the factory with the addition of building space stretching down to Wattle St. The elaborate mansarded entrances date to this period. In 1901 a further brick wing was added which took the buildings down to the Wattle St alignment.

The Bickford Smith manufactory lasted until 1912 when the site became the ‘Whiteworks factory’, then the Economic Clothing Factory’ and finally ‘Crestknit’. In recent years the site was bought by the Apostolic Church Trust for use as a place of worship and religious teaching.

Few factories of the 19th century survive with architecturally interesting features. Comparable but larger scale sites with architcturally interesting characteristics would be the surviving brewing towers in Collingwood and South Melbourne.

Associated People:

FORMER FUSE FACTORY - Permit Exemptions

General Exemptions:General exemptions apply to all places and objects included in the Victorian Heritage Register (VHR). General exemptions have been designed to allow everyday activities, maintenance and changes to your property, which don’t harm its cultural heritage significance, to proceed without the need to obtain approvals under the Heritage Act 2017.Places of worship: In some circumstances, you can alter a place of worship to accommodate religious practices without a permit, but you must notify the Executive Director of Heritage Victoria before you start the works or activities at least 20 business days before the works or activities are to commence.Subdivision/consolidation: Permit exemptions exist for some subdivisions and consolidations. If the subdivision or consolidation is in accordance with a planning permit granted under Part 4 of the Planning and Environment Act 1987 and the application for the planning permit was referred to the Executive Director of Heritage Victoria as a determining referral authority, a permit is not required.Specific exemptions may also apply to your registered place or object. If applicable, these are listed below. Specific exemptions are tailored to the conservation and management needs of an individual registered place or object and set out works and activities that are exempt from the requirements of a permit. Specific exemptions prevail if they conflict with general exemptions. Find out more about heritage permit exemptions here.Specific Exemptions:EXEMPTIONS FROM PERMITS:

(Classes of works or activities which may be undertaken without a permit under

Part 4 of the Heritage Act 1995)

Policy

The purpose of the permit exemptions is to allow works which do not impact on

the significance of the place to occur with out the need for a permit. The

interior of the former fuse factory has been so extensively altered that the

original purpose and layout of the building cannot be interpreted. On the

exterior the process of building extensions is the only remaining evidence of

the growth of this historic place. Both this ad-hoc growth and the

architectural elements such as the towers are of interest and give

significance to the site. Alterations to the exterior of the building

therefore should be the subject of permit applications. Alterations

(including demolition) to the unregistered cottage are permit exempt except

where the alterations can be classed as development of land L-1 such as

extensions or addition of floor space.

General Conditions:

1. All exempted alterations are to be planned and carried out in a manner

which prevents damage to the fabric of the registered place or object.

2. Should it become apparent during further inspection or the carrying out of

alterations that original or previously hidden or inaccessible details of the

place or object are revealed which relate to the significance of the place or

object, then the exemption covering such alteration shall cease and the

Executive Director shall be notified as soon as possible.

3. If there is a conservation policy and plan approved by the Executive

Director, all works shall be in accordance with it.

4. Nothing in this declaration prevents the Executive Director from amending

or rescinding all or any of the permit exemptions.

5. Nothing in this declaration exempts owners or their agents from the

responsibility to seek relevant planning or building permits from the

responsible authority where applicable.

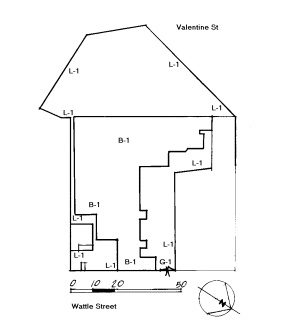

The Fuse Factory B-1

All internal alterations which do not affect the exterior of the registered

building are permit exempt.

The maintenance of the exterior joinery through repair (but not including

replacement) and painting in heritage colours is permit exempt.

Land L-1

The process of gardening, the maintenace of existing plantings and tress and

their removal is permit exempt

The unregistered cottage:

Interior alterations (including structural alterations) are permit exempt

External repainting and maintenance of the unregistered cottage is permit

exempt

Demolition of the unregistered cottage is permit exempt.

-

-

-

-

-

GOLDMINES HOTEL

Victorian Heritage Register H0827

Victorian Heritage Register H0827 -

FORMER BENDIGO GAOL

Victorian Heritage Register H1550

Victorian Heritage Register H1550 -

OLD POLICE BARRACKS

Victorian Heritage Register H0545

Victorian Heritage Register H0545

-

177 Fenwick Street

Yarra City

Yarra City -

19 Cambridge Street

Yarra City

Yarra City -

2 Derby Street

Yarra City

Yarra City

-

-