MOUNT HEPBURN COMPANY GOLD TREATMENT WORKS

CASSILIS ROAD TONGIO, EAST GIPPSLAND SHIRE

-

Add to tour

You must log in to do that.

-

Share

-

Shortlist place

You must log in to do that.

- Download report

Statement of Significance

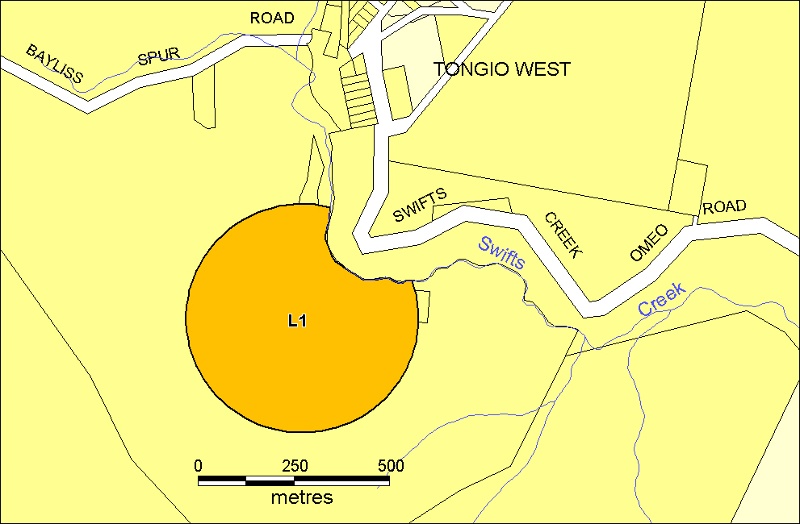

The Mount Hepburn Treatment Works is located near the junction ofPower'sGully and Swifts Creek. It is the site of major miningoperations from1896 to 1907 and the elaborate plant and processesrequired to extractgold from refractory ore (heavily mineralised goldbearing rock). Themine was also briefly worked in the 1930s and 1940s.It is a complicatedand extensive site with a series of adit levels,tramways and hut sitesand a palimpsest of ore processing relics on thebank of Swifts Creek.The significant components include but are notlimited to:

* stone piersvat foundations and discharge tramway.

* Dumps of cyanided and calcined battery sands and pond.

* Bed of large reverberatory furnace, remnants of flue, stack baseandother structures.

* Large ash dump containing ceramic and iron artefacts.

* Water-jacket blast furnace and small dump of slag.

* Clusters of scrap mining plant and vehicles.

* Barrel furnace, compressor, motor engine and associated material(slagand flint stones)

* Abandoned huts and sheds.

* Insitu stone crusher, milling machinery and associated structures.

* Earthworks including lower-most mullock heap, tramway andcutting,water race and concrete reservoir.

How is it significant?

The Mount Hepburn Treatment Works is of historical andscientificsignificance to the State of Victoria.

Why is it significant?

The Mount Hepburn Treatment Works is historically important as arareexample of a once widespread type. In the 1870s Victorian minersbeganto have success in extracting gold from refractory ores throughaprocess which involved roasting finely ground ore inreverberatoryfurnaces. In the late 1890s a new chemical process wasadded to theminer?s ore-retrieval repertoire which involved usingsolutions ofcyanide. The cyanide process proved to be extremelyimportant technologyand is still the basis of gold recovery in themining industry today.Example of both processes ? roasting and cyaniding- occurs at the siteand their importance at the time is clearlyillustrated by the scale ofthe surviving heritage.

The Mount Hepburn Treatment Works is scientifically important forthesurvival of a range of relics documenting attempts to treatrefractoryores through chemical and metallurgical means. Of crucialsignificanceis the remains of the cyanide works, the surviving featuresranging fromvery visible masonry structures to subtle traces. No otherplace inVictoria or possibly Australia can match the site, in extent,variety,archaeological or scientific potential in terms of surviving relics.

-

-

MOUNT HEPBURN COMPANY GOLD TREATMENT WORKS - History

Contextual History:History of Place:

In 1858, William Power made the first reef discovery in Gippsland near the junction of Power's Gully and Swifts Creek. His claim, named the Morning Light, formed part of the later Mt Hepburn–King Cassilis leases.The reefs in the vicinity of the later Mt Hepburn leases were first opened up in the late 1860s. A battery operated briefly, but was removed when the mines were abandoned in about 1870. The difficulty of retrieving gold from the complex, pyritic ore of the district was doubtless to blame for that early exodus.Mining entrepreneurs Ball and Smart took out leases on the Mt Hepburn ground in 1888, and initially crushed stone from their mine at their Brave George battery at Swift’s Creek. After the death of Smart in 1889, Ball continued the development of the mine. In 1893, his Mt Hepburn Co. installed an Otis ball mill (one of the first in Victoria) and short blanket tables, driven by 16-hp portable steam engine. The plant cost relatively little to run, but its lack of concentrating plant caused a substantial loss of gold in the tailings and operations were halted at the end of 1895. At that time, the Government Geologist, R.A.F. Murray, visited the mine and hailed it as the most remarkable on the field—at least, in terms of its potential yields. But he lamented that the company’s inadequate treatment plant allowed at least half the gold to escape with the tailings.In 1896, an English company, the Mt Hepburn Co. Ltd, was formed to take over the leases. The Otis mill was replaced by a traditional stamp battery made by Thompsons of Castlemaine. A 60-head battery was originally ordered, but was deemed excessive and only 20 heads were eventually delivered. A 90-horsepower boiler, intended to drive the 60-head battery, was also delivered but was never used. Also superfluous was a 60-ft high brick chimney stack, built on the hillside near the battery to serve the large boiler. Other works developed at this time included a water race from Upper Swifts Creek, water storage, and a new tramway from the Beehive level of the mine. In 1897, the Mt Hepburn Co. contracted with the General Exploration Co. (GEC) that the GEC could treat all its tailings. In return, the GEC agreed to build a cyanide treatment plant and pay the Mt Hepburn Co. a royalty on gold retrieved. In 1898, GEC constructed a large cyanide plant, costing £7,000 and said to be one of the best in Australia at that time.In September 1898, after just three months’ continuous crushing with their new battery, the Mt Hepburn Co. ceased operations, due to negligible gold returns. The stamp battery had achieved poorer returns than the old Otis mill: only 207 oz from 2,893 tons of ore. Summarising the performance of the Mt Hepburn Co. Ltd., Griffiths (1978) wrote that it ‘was floated on the premise of huge ore reserves and simple metallurgy, neither of which were investigated properly at the time, and both of which were quickly found to be incorrect.’ Shareholders lost some £180,000. The crushing plant was sold to the Cassilis GMC in 1900.The GEC’s cyaniding plant had commenced work in mid-1898. It was soon found that the plant’s operational capacity was only 720 tons per month, rather than the 3,000 tons anticipated. The complexities of the local ore resulted in low gold recovery, demanded a large consumption of lime, and lengthened the cyaniding process. Proving unprofitable, operations ceased in early 1900, and the cyanide plant was sold to the Allsop brothers (its former managers). At the same time, they acquired outbuildings, chimney stack, engine bases, and other structures from the defunct Mt Hepburn Co. The Allsops constructed an integrated treatment works on the Mt Hepburn site. Recognising the need to treat the pyritic Cassilis ores in a furnace prior to cyanidation, they installed a large desulphurising roasting furnace, complete with condensing chamber and 360ft-long ground flue connected to the unused 60-ft chimney. The furnace occupied the GEC’s former extraction house, between the southerly group of vat bases and the creek. It was one of the largest ore-roasting furnaces in Victoria, measuring 50 ft long and 10 ft high. In July 1901, J.L. Allsop, manager of the plant, died, aged just 34, as a result of inhaling the poisonous gases generated by the cyanide process.The Allsops’ plant treated tailings from local mines and from as far away as Sunnyside and Glen Wills. In fact, in 1901 most of the plant was moved to Sunnyside, to treat the huge volume of tailings on-site. Between 1900-03, it is estimated that the plant at Mt Hepburn treated 2,500 tons of concentrates and tailings for a yield of about 5,000 oz. The gold recovery process was said to have been nearly 95 per cent effective. In 1902, the King Cassilis GMC was formed. From 1904, the company rented Allsop’s treatment works, gradually modifying the plant to incorporate an economical Merton furnace, Dodge rock breaker, and a Niagara pulveriser (later replaced by a Krupp ball mill). The plant’s small size and unsuitability for the hard local ore resulted in poor yields, and the mine closed down in 1906. Since 1888, the Mt Hepburn/King Cassilis mine had yielded 1,852 oz from 4,172 tons of ore.In 1907, the remaining useful components of Allsop’s treatment works were removed to sites at Glen Wills and Sunnyside, and over the ensuing few years operations at Mt Hepburn were confined to the cyaniding of tailings remaining on the site. Some small-scale prospecting and mining took place prior to World War One. The King Cassilis leases were worked by the National Gold Mining and Milling Co. in the early 1930s. A small plant was installed, consisting of a 5-head battery with two concentrating tables, a small hand-charged reverberatory furnace, and cyanide plant. Only 220 tons of ore were treated, for a yield of 114 oz.J.D. Avery took up the leases in the late 1940s and erected a small water-jacketted blast furnace, in which he smelted ore for many years.MOUNT HEPBURN COMPANY GOLD TREATMENT WORKS - Assessment Against Criteria

Criterion

Criterion A

The historical importance, association with or relationship to Victoria's history of the place or object.

The Mount Hepburn Treatment Works is historically important as a rare example of a once widespread type. In the 1870s Victorian miners began to have success in extracting gold from refractory ores through a process which involved roasting finely ground ore in reverberatory furnaces. In the late 1890s a new chemical process was added to the miner's ore-retrieval repertoire which involved using solutions of cyanide. The cyanide process proved to be extremely important technology and is still the basis of gold recovery in the mining industry today. Example of both processes - roasting and cyaniding - occurs at the site and their importance at the time is clearly illustrated by the scale of the surviving heritage.

Criterion B

The importance of a place or object in demonstrating rarity or uniqueness.

The Mount Hepburn Treatment Works is historically important as a rare example of a once widespread type. In the 1870s Victorian miners began to have success in extracting gold from refractory ores through a process which involved roasting finely ground ore in reverberatory furnaces. In the late 1890s a new chemical process was added to the miner's ore-retrieval repertoire which involved using solutions of cyanide. The cyanide process proved to be extremely important technology and is still the basis of gold recovery in the mining industry today. Example of both processes - roasting and cyaniding - occurs at the site and their importance at the time is clearly illustrated by the scale of the surviving heritage.

Criterion C

The place or object's potential to educate, illustrate or provide further scientific investigation in relation to Victoria's cultural heritage.

The Mount Hepburn Treatment Works is scientifically important for the survival of a range of relics documenting attempts to treat refractory ores through chemical and metallurgical means. Of crucial significance is the remains of the cyanide works, the surviving features ranging from very visible masonry structures to subtle traces. No other place in Victoria or possibly Australia can match the site, in extent, variety, archaeological or scientific potential in terms of surviving relics.

Criterion D

The importance of a place or object in exhibiting the principal characteristics or the representative nature of a place or object as part of a class or type of places or objects.

Criterion E

The importance of the place or object in exhibiting good design or aesthetic characteristics and/or in exhibiting a richness, diversity or unusual integration of features.

Criterion F

The importance of the place or object in demonstrating or being associated with scientific or technical innovations or achievements.

The Mount Hepburn Treatment Works is scientifically important for the survival of a range of relics documenting attempts to treat refractory ores through chemical and metallurgical means. Of crucial significance is the remains of the cyanide works, the surviving features ranging from very visible masonry structures to subtle traces. No other place in Victoria or possibly Australia can match the site, in extent, variety, archaeological or scientific potential in terms of surviving relics.

Criterion G

The importance of the place or object in demonstrating social or cultural associations.

Criterion H

Any other matter which the Council considers relevant to the determination of cultural heritage significance

technology.

MOUNT HEPBURN COMPANY GOLD TREATMENT WORKS - Permit Exemptions

General Exemptions:General exemptions apply to all places and objects included in the Victorian Heritage Register (VHR). General exemptions have been designed to allow everyday activities, maintenance and changes to your property, which don’t harm its cultural heritage significance, to proceed without the need to obtain approvals under the Heritage Act 2017.Places of worship: In some circumstances, you can alter a place of worship to accommodate religious practices without a permit, but you must notify the Executive Director of Heritage Victoria before you start the works or activities at least 20 business days before the works or activities are to commence.Subdivision/consolidation: Permit exemptions exist for some subdivisions and consolidations. If the subdivision or consolidation is in accordance with a planning permit granted under Part 4 of the Planning and Environment Act 1987 and the application for the planning permit was referred to the Executive Director of Heritage Victoria as a determining referral authority, a permit is not required.Specific exemptions may also apply to your registered place or object. If applicable, these are listed below. Specific exemptions are tailored to the conservation and management needs of an individual registered place or object and set out works and activities that are exempt from the requirements of a permit. Specific exemptions prevail if they conflict with general exemptions. Find out more about heritage permit exemptions here.Specific Exemptions:General Conditions:

1. All exempted alterations are to be planned and carried out in a manner which prevents damage to the fabric of the registered place or object.

2. Should it become apparent during further inspection or the carrying out of alterations that original or previously hidden or inaccessible details of the place or object are revealed which relate to the significance of the place or object, then the exemption covering such alteration shall cease and the Executive Director shall be notified as soon as possible.

3. If there is a conservation policy and plan approved by the Executive Director, all works shall be in accordance with it.

4. Nothing in this declaration prevents the Executive Director from amending or rescinding all or any of the permit exemptions.

Nothing in this declaration exempts owners or their agents from the responsibility to seek relevant planning or building permits from the responsible authority where applicable.

Exemptions of Permit

No permits are required for the following classes of works:

* Works required to leave abandoned adits or other earthworks in a safe condition.

* Undertaking of safety and other works to restrict vehicular access to the site and minimise removal of machinery and foot traffic near or on foundations.

* Repairs to the tailings pond.

* Installation of information signage for interpretation and public risk purposes.

* On-site works confined to protect and stabilise buildings and structures.

* Repairs to buildings which replace like with like.

* Control of pest plants and animals.

* Preliminary mineral exploration involving geological, geophysical, and geochemical surveys.

Exemption Review

Permit exemptions will be reviewed in conjunction with a Conservation Management Plan when supplied by the owners and to the satisfaction of the Executive Director.MOUNT HEPBURN COMPANY GOLD TREATMENT WORKS - Permit Exemption Policy

Policy

Through the registration of the Mount Hepburn Treatment Works it is desired to retain the essential character of the place. The intent of the permit exemptions is to allow the normal day to day management of the site as a key component of the Cassilis Historic Reserve. The permit exemptions recognise the relative remoteness of the place and that there is a current mining licence over the place.

-

-

-

-

-

MOUNT HEPBURN COMPANY GOLD TREATMENT WORKS

Victorian Heritage Register H1940

Victorian Heritage Register H1940 -

MT HEPBURN COMPANY GOLD TREATMENT WORKS

Victorian Heritage Inventory

Victorian Heritage Inventory

-

13 Flinders Street, Queenscliff

Queenscliffe Borough

Queenscliffe Borough -

162 Nicholson Street

Yarra City

Yarra City -

164 Nicholson Street

Yarra City

Yarra City

-

-